Investigation summary

What happened

On the morning of 4 November 2023, a Gulfstream 695A, registered VH‑HPY, was being operated by AGAIR on an instrument flight rules flight from Toowoomba to Mount Isa, Queensland. On board the aircraft were the pilot and 2 camera operators. The purpose of the flight was to conduct line scanning of fire zones located north of Mount Isa.

About 1 hour and 50 minutes into the flight, while the aircraft was in cruise at flight level 280, air traffic control (ATC) lost radio contact with the pilot. Over the following 30 minutes, ATC made multiple attempts to re‑establish contact, including using alternate frequencies and relaying messages via other aircraft in the vicinity. VH-HPY was observed diverging from track and ATC declared an uncertainty phase for the aircraft.

About 20 minutes later, ATC called the pilot’s mobile telephone, and a brief conversation took place. During the conversation, the pilot’s speech was observed as slow and flat. In response, ATC upgraded the aircraft’s status to an alert phase and initiated their hypoxic pilot emergency procedures. About 10 minutes later, the crew of a nearby aircraft was able to establish contact with the pilot, having been requested to do so by ATC. The alert phase was downgraded to an uncertainty phase and, a short time later, ATC re-established direct contact with the pilot. The uncertainty phase was cancelled 1 minute later.

The pilot confirmed that their oxygen system was operating normally, and they were issued a clearance to undertake line scanning north of Mount Isa. Over the following 4 minutes, the pilot repeated the clearance from ATC 4 times, seeming uncertain about the status of the clearance. The radio recordings during this period indicate that the pilot’s rate and volume of speech had substantially lowered from earlier communications and was worsening. The pilot’s final radio transmission displayed the slowest speaking rate of all their communications during the flight and contained stuttering and operational mistakes. Air traffic control did not attempt to re‑establish contact with the pilot until about 18 minutes later, however no further responses from the pilot were received.

A short time later, the aircraft departed controlled flight, initially entering a descending anticlockwise turn with an increasing rate of descent. At about 10,500 ft, the aircraft likely transitioned into an aerodynamic spin, with a subsequent average rate of descent of about 13,500 ft/min. The aircraft collided with terrain 55 km south-east of Cloncurry. The 3 occupants were fatally injured, and the aircraft was destroyed by impact forces and a fuel-fed post-impact fire.

What the ATSB found

The ATSB found that the aircraft had a long-term intermittent defect with the pressurisation system that would manifest as a reduced maximum attainable cabin differential pressure. The defect was known about by senior AGAIR management who attempted to have the defect rectified. However, they did not formally record the defect, communicate it to the safety manager, undertake a formal risk assessment of the issue, or provide explicit procedures to pilots for managing it.

Instead, AGAIR management personnel participated in and encouraged the practice of continuing operations in the aircraft at a cabin altitude that required the use of oxygen, without access to a suitable oxygen supply. This included the pilot of the accident flight, with emails and historical flight data indicating they had a pattern of normalised deviation from safe operating practices by continuing to operate the aircraft when the pressurisation system was defective. In these situations, the pilot was found to have managed the effects of hypoxia by undertaking short descents to lower altitudes and use of the aircraft’s oxygen system, which was designed for emergency use only.

It was identified that during the accident flight the pressurisation system probably did not maintain the required cabin altitude, and the pilot probably continued the flight using the aircraft’s oxygen system, which was unsuitable for this purpose. The pilot’s speech, as captured by air traffic control recordings, demonstrated significant and progressive impairment while the aircraft was operating at about flight level 280. This impairment was consistent with altitude hypoxia, which almost certainly significantly degraded the pilot’s ability to safely operate the aircraft.

While the aircraft was in cruise, both power levers were probably reduced without a descent being initiated, resulting in a progressive reduction of airspeed. The aircraft then entered a descending anticlockwise turn with an increasing rate of descent. At around 10,500 ft control input(s) were almost certainly made, probably an attempt to recover, that transitioned the aircraft from a high‑speed descent to an unrecoverable spin condition that continued until the impact with terrain.

It was found that the AGAIR head of flying operations (HOFO) did not communicate critical safety information about the known intermittent pressurisation defect when they were phoned by air traffic control about concerns that the pilot was impacted by hypoxia around 37 minutes before the collision. This took place at a time when air traffic control could have taken action to instruct the pilot to descend to a safe altitude.

Air traffic control personnel involved therefore had no knowledge of the aircraft pressurisation defect from that phone call, and without establishing with the pilot why they had not responded to ATC broadcasts for 1 hour and 13 minutes, they likely reduced their vigilance about hypoxia after being told by the pilot that operations were normal. Consequently, ATC did not re-identify the possibility of hypoxia during the subsequent progressive deterioration of the pilot’s speech. Additionally, the air traffic control ‘hypoxic pilot emergency checklist’ contained no guidance on ceasing the emergency response, which increased the risk of inappropriately downgrading the response during a developing hypoxic scenario.

It was also identified that AGAIR Gulfstream 690 and 695 aircraft were operated with known defects without being recorded on the aircraft’s maintenance releases, likely as a routine practice. This issue had been reported to CASA in 2019 and a surveillance event was conducted in response. The scope of the surveillance event did not include a crosscheck of maintenance releases against the aircraft logbooks, limiting the ability to determine whether any non-reporting and improper deferral of defects had been taking place at that time.

What has been done as a result

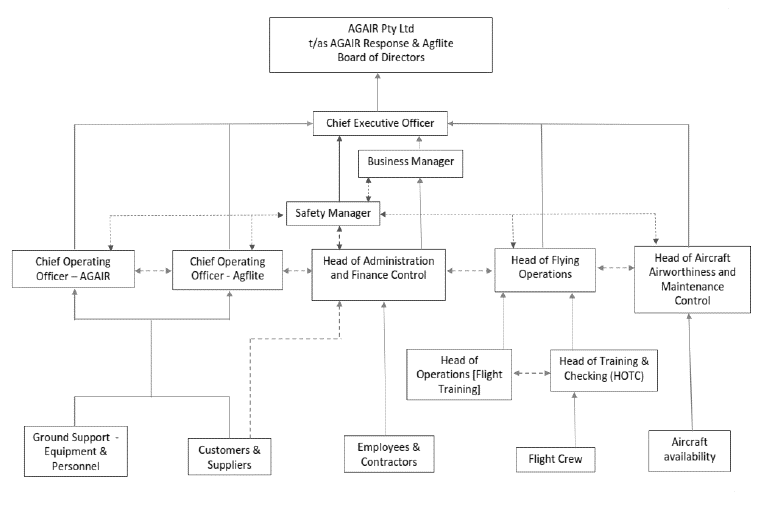

AGAIR amended the organisation’s procedural documentation to provide greater detail on the delegation of management responsibilities, maximum cabin altitude requirements, defect reporting, and the capture of cabin pressure information as part of daily aircraft flight and fuel logs.

AGAIR also incorporated pressurisation, oxygen and line scanning hazards within the organisation’s hazard register. AGAIR has also contracted a continuing airworthiness management organisation and appointed a new head of aircraft airworthiness maintenance control to monitor defect reporting.

While the ATSB recognises the changes implemented by AGAIR to date, the actions taken do not address the matters raised relating to effective operational control. The HOFO was responsible for ensuring the operation was compliant with aviation legislation and conformed to company standards. However, the ATSB found multiple instances where these requirements were not met. AGAIR has not addressed how the organisation intends to assure future legislative and procedural compliance by line pilots and management personnel. As such, the ATSB has issued a formal safety recommendation to AGAIR to initiate an independent review of their organisational structure and oversight of operational activities to assure ongoing effective operational control by management.

Airservices Australia advised that it is in the process of conducting a review of the hypoxia in-flight emergency response checklist.

Safety message

This accident highlights the dangers of operational practices that intentionally circumvent critical safety defences. The acceptance of these actions at an individual and organisational level normalises that behaviour and exposes the operation to an unnecessarily increased level of risk.

This accident also underscores the insidious and deadly potential of altitude hypoxia, and pilots need to be alert to this significant hazard when operating at high altitude. Life support and emergency alerting systems are often the final line of defence against hypoxic incapacitation, and they should only be used in accordance with the manufacturer’s procedures.

The occurrence

Overview

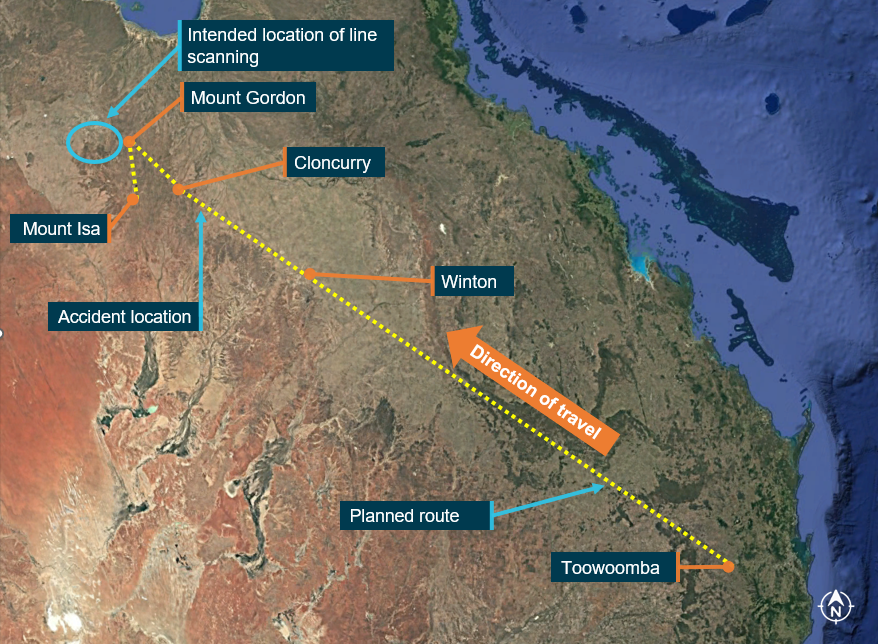

On the morning of 4 November 2023, a Gulfstream 695A, registered VH‑HPY, was being operated by AGAIR on an instrument flight rules[1] flight from Toowoomba to Mount Isa, Queensland, with the callsign ‘birddog 370’. On board the aircraft were the pilot and 2 camera operators. The purpose of the flight was to conduct line scanning[2] of fire zones located north of Mount Isa. The flight had been contracted by Queensland Fire and Emergency Services and was conducted as an aerial work operation.

While the aircraft was in cruise at flight level[3] (FL) 280, air traffic control (ATC) radio contact with the pilot was unable to be maintained. ATC made multiple attempts to re-establish radio communications, but these were initially unsuccessful. ATC also declared an uncertainty phase for the aircraft, later upgrading it to an alert phase. After about 1 hour, the crew of a Royal Australian Air Force (RAAF) aircraft was able to make radio contact with the pilot, and ATC re-established communications a short time later. The alert and uncertainty phases were subsequently cancelled.

A series of radio communications were exchanged between the pilot and ATC, during which the pilot was issued a clearance to undertake line scanning north of Mount Isa. The pilot did not respond to any further calls from ATC. The aircraft departed controlled flight and at 1427 (local time) collided with terrain 55 km south-east of Cloncurry (Figure 1). The 3 occupants were fatally injured, and the aircraft was destroyed.

Figure 1: Flight path overview

Source: Google Earth, annotated by the ATSB

Departure, climb and cruise

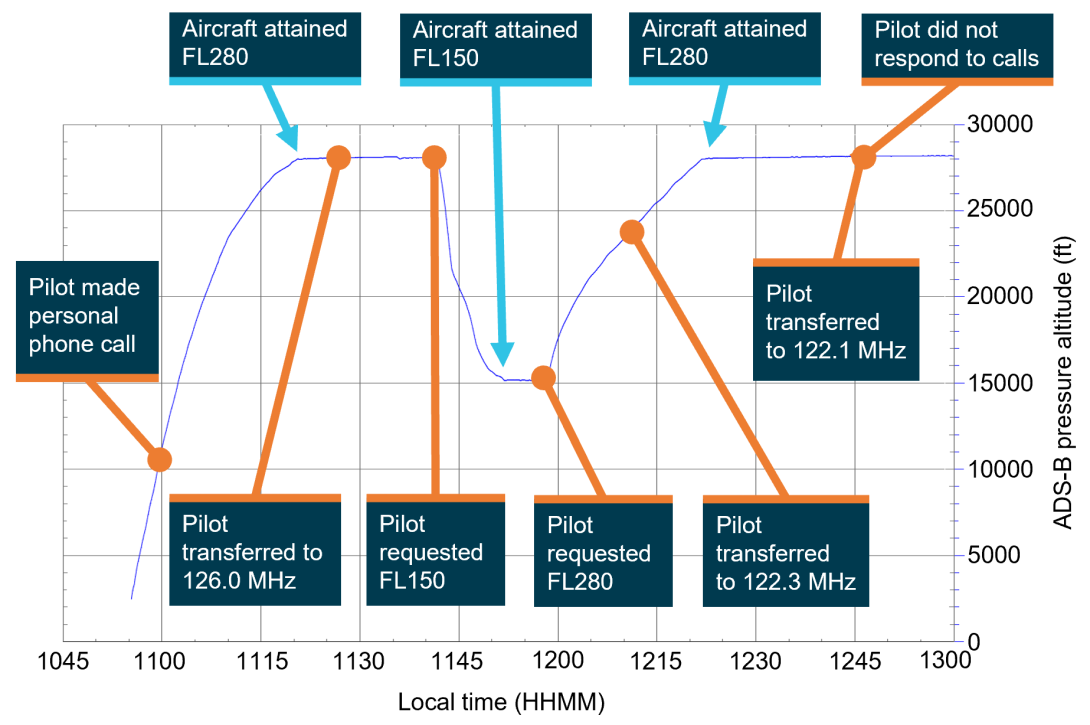

At 1055 on the morning of the accident flight, the aircraft departed Toowoomba Airport with the pilot being provided an ATC clearance for the flight to track to Mount Isa. The pilot was initially cleared by ATC to climb to FL160 and was then issued further instruction to continue the climb to the planned cruise of FL280. The pilot made a brief personal phone call at about 1103 (see Telecommunications), and the aircraft reached FL280 at 1120:30 (Figure 2).

Figure 2: Plot of changes in aircraft altitude and the sequence of radio communication events throughout the accident flight from 1045–1300

Position information including altitude and time was obtained from ADS-B data that was broadcast from VH-HPY. Source: ATSB

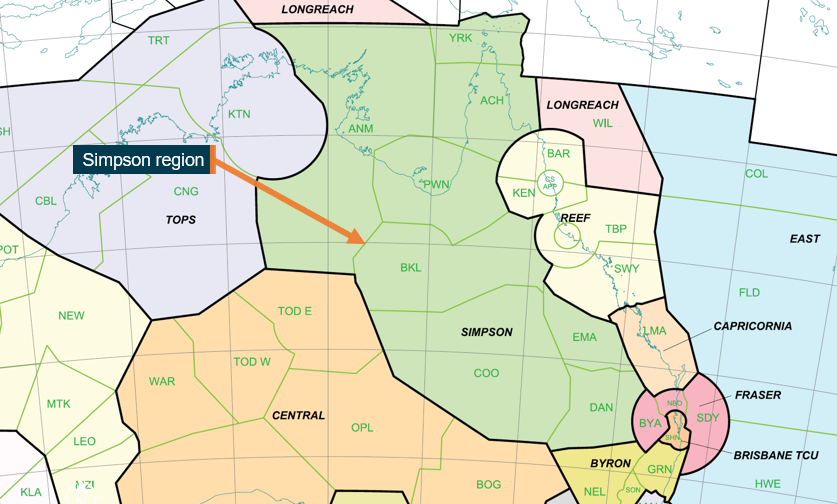

At 1126:55 the flight was transferred to, and the pilot established radio communication with, the controller responsible for the Simpson region on the frequency 126.0 MHz (see Airspace).

At 1141:12, the pilot contacted the controller and requested clearance to descend to FL150. The requested clearance was provided and, a short time later, the aircraft started to descend. The initial rate of descent reached about 3,900 feet per minute (ft/min), but this slowed as the aircraft continued to descend. At 1151:49, the aircraft levelled off at FL150. At 1157:43, the pilot contacted the controller again and requested clearance to climb back to FL280, which was approved. Shortly after, the aircraft began to climb.

At 1210:19, the Simpson region controller requested the pilot change their radio communication frequency to 122.3 MHz, to maintain radio contact with ground equipment as the aircraft flew further west. The pilot established radio communication on the new frequency and reported to the controller that the aircraft was on climb to FL280. At 1221:49, the aircraft levelled off at FL280.

At 1245:51, the Simpson region controller requested the pilot change their radio communication frequency to 122.1 MHz as the aircraft continued its journey to the northwest. This change was acknowledged by the pilot, but the controller did not receive radio communications from the flight on the newly-assigned frequency.

Initial loss of radio communications

Between 1247:51 and 1317:48, the Simpson region controller made 12 separate radio broadcasts attempting to re-establish radio communication with the pilot. The controller also attempted to contact the pilot on high frequency radio, and by relaying messages via the flight crew of a passenger transport aircraft that was operating in the vicinity of VH-HPY.

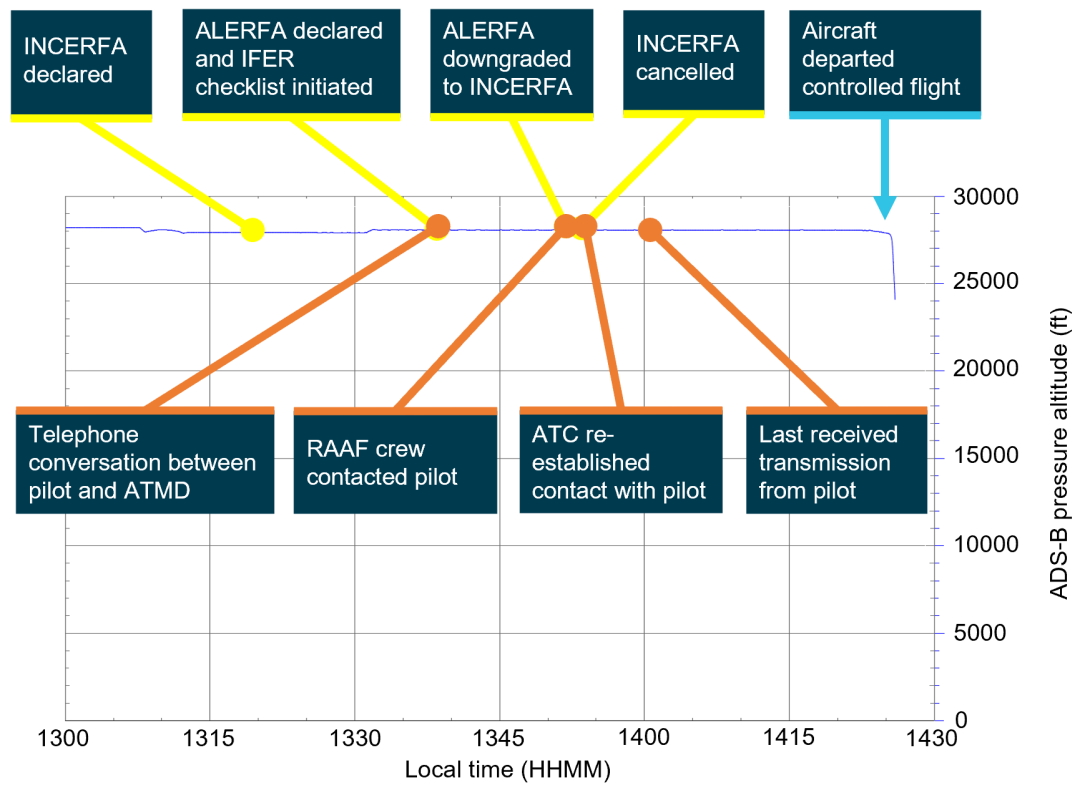

During this time the controller identified that VH-HPY was diverging from track, by about 2 km laterally, and the shift manager (SM) was informed (see Air traffic services). At 1318:20, ATC declared an uncertainty phase (INCERFA)[4] (see Emergency phases) and the air traffic management director (ATMD) was made aware of the developing situation (Figure 3).

Figure 3: Sequence of ATC actions and communication events between 1300–1430

Position information including altitude and time was obtained from ADS-B data that was broadcast from VH-HPY. Source: ATSB

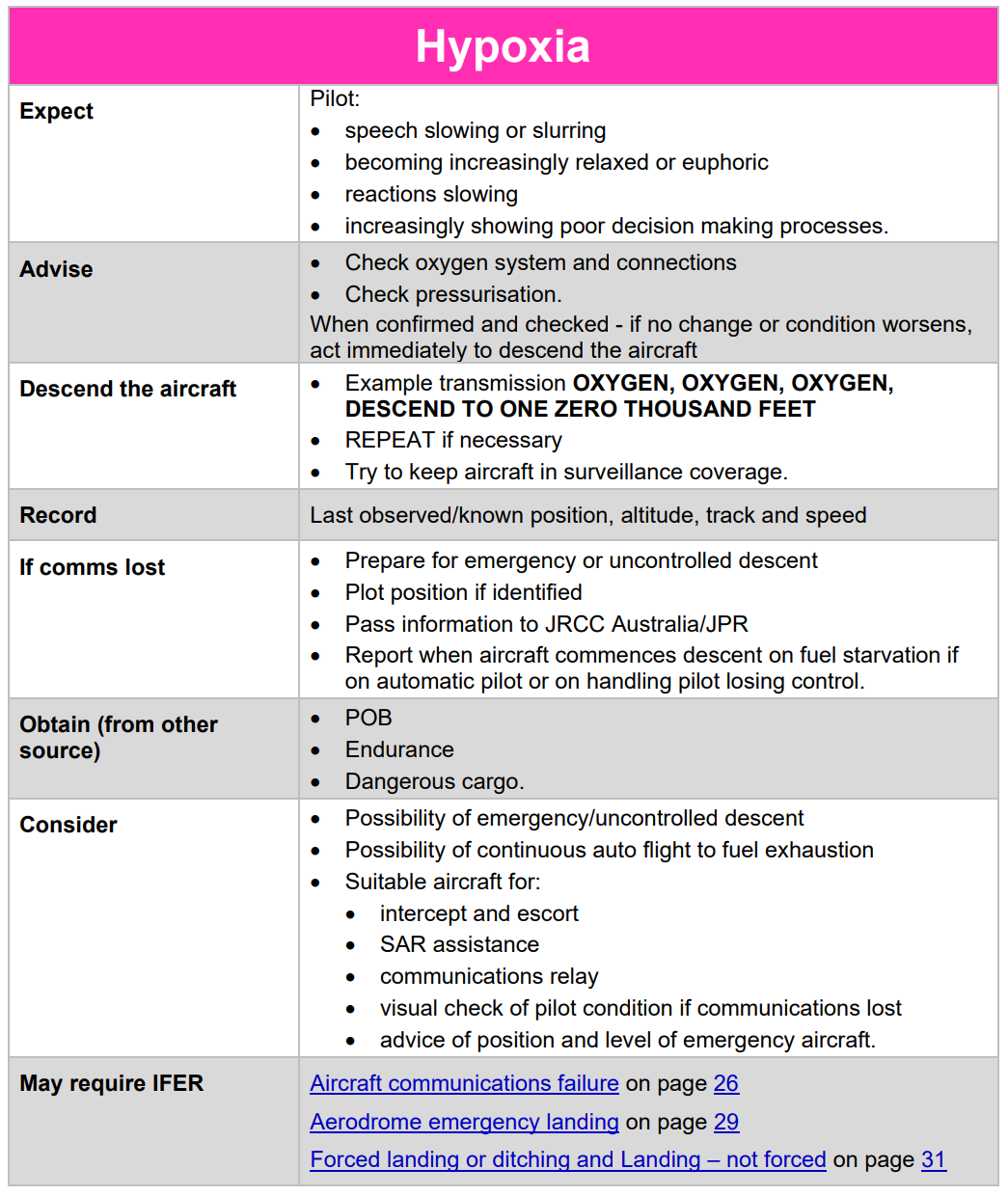

At 1337:46, the ATMD attempted to contact the pilot using the mobile telephone number listed on the flight plan, but the pilot did not answer the call. At 1338:36, the pilot returned the ATMD’s phone call, and they had a brief conversation during which the pilot advised that they had ‘no joy’ on radio frequency 122.4 MHz, rather than the instructed frequency of 122.1 MHz (see Telecommunications). The ATMD determined that the pilot’s speech was ‘slower’ than normal and ‘flat’, and these concerns were shared with the SM at the conclusion of the call. At 1340:00, the INCEFRA was upgraded to an alert phase (ALERFA)[5] (see Emergency phases) and the hypoxic pilot in-flight emergency response (IFER) checklist was initiated (see Hypoxic pilot procedures).

At 1340:15, the controller commenced radio broadcasts to the pilot as part of the IFER hypoxia checklist. These transmissions included the instructions:

- Oxygen, oxygen, oxygen, descend to one zero thousand feet.

At the same time, the ATMD called the pilot’s mobile phone, but the pilot did not answer. The ATMD left a voicemail message requesting the pilot check their oxygen and call back ATC.

At 1341:11, the crew of a RAAF aircraft that was in the vicinity of VH-HPY offered to assist the controller to contact the pilot. The controller agreed and a short time later the RAAF crew reported hearing a broken transmission, possibly from VH-HPY, but they were unable to establish contact with the pilot.

At 1341:31, the pilot of VH-HPY transmitted a radio broadcast on frequency 122.1 MHz, providing callsign, flight level, and radio frequency, but the controller was unable to re-establish 2-way communications. Between 1341:31 and 1350:51, the controller continued to broadcast instruction for the pilot to descend the aircraft to 10,000 ft. The controller also attempted further relays via other aircraft in the vicinity of VH‑HPY on various frequencies, including the international air distress frequency 121.5 MHz.

At about 1348:00, ATC sent 2 text messages to the pilot’s mobile phone and an email requesting they check their oxygen and pressurisation and contact them on frequency 122.1 MHz. No response was received.

Re-establishment of radio communications

At 1349:13, the crew of the RAAF aircraft advised the controller that they had heard a ‘weak’ transmission from the pilot of VH-HPY on frequency 118.6 MHz. In response, the controller requested the crew of the RAAF aircraft make another broadcast to include the statement ‘oxygen, oxygen, oxygen descend to one zero thousand feet’. The crew of the RAAF aircraft made 2 such broadcasts and, at about 1350, they established contact with the pilot of VH-HPY.

During this time, the ATMD and SM telephoned the AGAIR head of flying operations (HOFO), advising that contact had been lost with the pilot of VH-HPY and that they suspected the pilot was potentially affected by hypoxia (see Telecommunications).

At 1350:50 the crew of the RAAF aircraft relayed to the controller that VH‑HPY was ‘ops normal’ and maintaining FL280. ATC subsequently downgraded the ALERFA to an INCERFA. At 1351:08, the controller requested that the RAAF crew instruct the pilot to call ATC on frequency 123.95 MHz. At 1351:59, the controller re-established radio communications with the pilot of VH‑HPY on this frequency and the pilot reported ‘ops normal’. About 1 minute later, ATC cancelled the INCERFA phase.

Between 1352:08 and 1357:34, several communications took place between the controller and the pilot. During this time, and 2 minutes after ATC had cancelled the INCERFA phase, the controller asked the pilot ‘just confirm your oxygen system is ops normal’, to which the pilot responded ‘affirm’. The controller later recalled that they had asked about the oxygen system because they had concerns there was a potential hypoxia event and wanted the pilot to look at the oxygen system in case there was a problem. The ATMD recalled that they requested the controller query the status of the oxygen system as a ‘surety check’. The controller recalled that the pilot’s speech at that time was ‘clear and concise’, and they were satisfied with the pilot’s delivery of speech.

At 1357:34, the pilot was provided with an ATC clearance to undertake operations near Mount Gordon. ATC communication recordings showed that the pilot confirmed the clearance at 1357:43, and then twice requested confirmation that the controller had copied their clearance readback (1359:26 and 1400:15). The controller then responded at 1400:19, advising the pilot that the communications were at low strength and could the pilot adjust their microphone. The pilot replied at 1400:57 and the controller then confirmed they had received the pilot’s confirmation of the clearance. At 1401:23 the pilot then confirmed the clearance again. The controller recalled that, during this time, a lot of activity took place near their console related to the status of the aircraft (see Simpson region controller divided attention).

The radio recordings indicate that the pilot’s rate and volume of speech had substantially decreased from earlier communications and were worsening. During the radio transmission that commenced at 1401:23 the pilot had difficulty pronouncing the location ‘Cloncurry’ and they incorrectly stated the airwork would take place near ‘Mount Ball’, which was then corrected to ‘Gordon’.

At 1419:19, the controller requested the pilot change frequency to 122.4 MHz, but no response was received. Between 1419:19 and 1427:15 the controller attempted to contact the pilot 8 times without receiving a response.

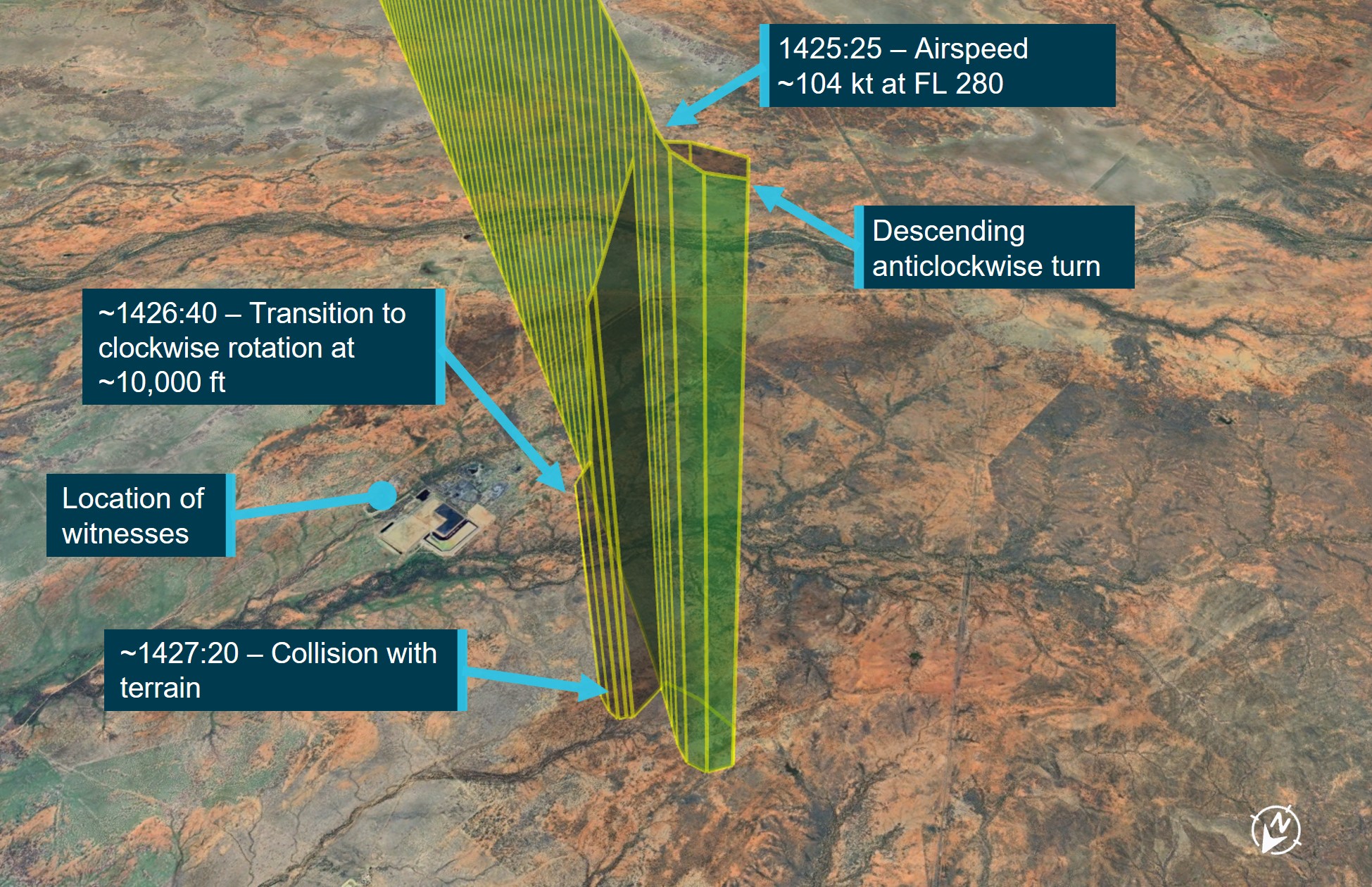

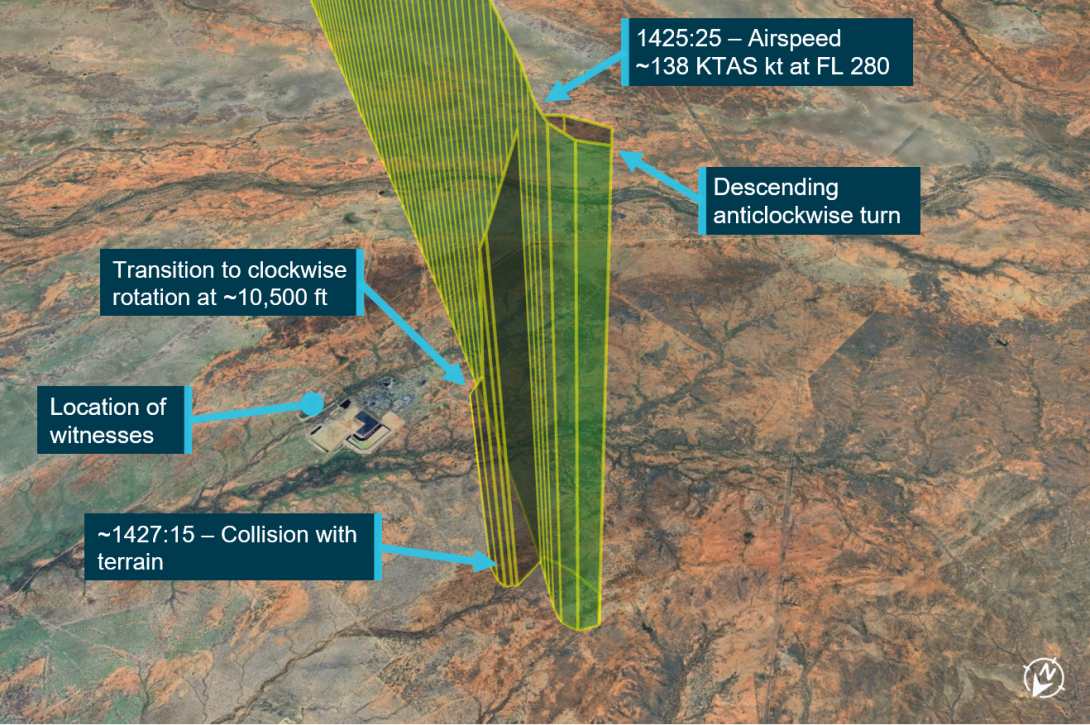

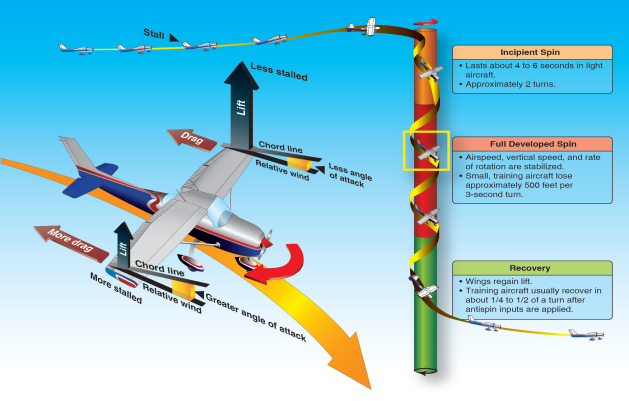

Departure from controlled flight

Recorded data indicated that, at 1423:20, the aircraft’s airspeed began to reduce from a cruise airspeed of about 236 KTAS.[6] At 1425:25, the airspeed had decreased to about 138 KTAS and the aircraft departed controlled flight (see Flight performance analysis). The aircraft initially entered a descending anticlockwise[7] turn with an increasing rate of descent. At an altitude of about 10,500 ft, the aircraft transitioned into a tight clockwise helical descent, likely an aerodynamic spin,[8] with a subsequent average rate of descent of about 13,500 ft/min (Figure 4).

Figure 4: Flight path of VH-HPY during the descent from FL280

Source: Google Earth, annotated by the ATSB

Two witnesses at a nearby mining facility observed the aircraft descending in a nose-down, clockwise, corkscrew motion and described hearing a ‘whirring’ noise. The witnesses recalled that motion momentarily stopped part way down, before re-entering the nose-down corkscrew descent.

At about 1427:15, the aircraft collided with terrain 55 km south-east of Cloncurry. The 3 occupants were fatally injured, and the aircraft was destroyed by impact forces and a fuel-fed post-impact fire.

Context

Personnel information

Pilot

Aeronautical experience

The pilot held an air transport pilot licence (aeroplane) and a commercial pilot licence (helicopter), issued in February 2005 and August 2009, respectively. At the time of the accident, the pilot had accumulated about 4,900 hours total aeronautical experience, which included about 3,200 hours operating turboprop, jet, and high-performance Royal Australian Air Force (RAAF) military aircraft. This included unpressurised aircraft with supplemental oxygen systems (Pilatus PC-9) and pressurised aircraft (Beechcraft B200 and Learjet L35/36). Training records provided by the RAAF indicated the pilot had completed 2 altitude chamber training exercises,[9] one in 1995 and the second in 2019.

Gulfstream 695A training and experience

In August 2023, the pilot commenced work with AGAIR. They had not previously flown a Gulfstream 695A.

On 15 August 2023, the pilot undertook Gulfstream 695A training and completed a flight review the following day. This training was arranged by AGAIR, and undertaken in VH-HPY, but the training and review were conducted by an independent training provider.

During the training, the pilot demonstrated competent use of the aircraft systems including management of the pressurisation system. The pilot also conducted a simulated depressurisation scenario from FL150, which involved the use of oxygen and an emergency descent. The training notes made by the instructor about the pilot’s performance during this activity stated:

Emergency descent - best initiated with roll, using the secondary effect (yaw) to pitch the nose down to the required attitude without causing negative load factor.

The training and flight review were completed within 2.9 hours of flight time and the pilot was assessed by the instructor as competent to operate the aircraft type as pilot in command (PIC). The pilot commenced flying as PIC for AGAIR on 28 September 2023 and they were initially supervised by the AGAIR chief operating officer (COO) over ‘3 or 4 flights’ (see AGAIR chief operating officer actions). There was no training file kept on the pilot’s performance during the supervised flights.

In the 3 months after starting with the operator until the accident, they had accumulated a total of about 102 hours flight time, all flying VH-HPY mostly undertaking line scanning flights from Toowoomba.

After review of the draft ATSB investigation report the operator provided a record indicating the pilot of the accident flight completed a ‘line check’ flight in VH-HPY on 9 August 2023 with the AGAIR head of flying operations (HOFO).

Medical information

The pilot held a class 1 aviation medical certificate that was issued on 27 February 2023 and was valid at the time of the accident. Their certificate had a restriction requiring reading correction to be available while exercising the privileges of their licence. The pilot’s aviation medical records were provided for the period 2022–2023 and their general practitioner records were provided for the period 2021–2023. Overall, these records indicated no significant medical conditions or abnormal physical findings.

At the time of the accident, the pilot was taking medication for high cholesterol. In 2019 they underwent a coronary angiography, which showed no calcium and no soft plaque formation. The pilot had also visited a cardiologist in December 2021 due to family history, and undertook a stress electrocardiogram in November 2022, which identified no issues. In April 2023, the pilot injured their Achilles tendon and underwent surgical repair. The injury was reported to the Civil Aviation Safety Authority (CASA) on 18 April 2023, and the pilot was cleared to resume flying duties on 22 May 2023. The pilot was reported to have recovered well from their Achilles injury. Overall, the pilot was reported to have been fit, active and healthy, with no known stressors.

Recent history

The pilot had 8 duty free days prior to the commencement of their most recent period of duty. This period started on 1 November 2023. They conducted a 1.3 hour flight from Essendon, Victoria, to Hay, New South Wales, on 1 November, and a 3.7 hour flight from Hay to Toowoomba on 2 November.

The pilot was reported to have gone to bed at around 2030–2100 the night prior to the accident and was known to wake early and undertake morning exercise. The collision with terrain occurred mid-afternoon after they had been flying about 3.5 hours that day. The ATSB reviewed their recent work-rest history and based on the available evidence, it was considered very unlikely that the pilot was experiencing a level of fatigue known to adversely affect performance.

Camera operator 1

Aeronautical experience

Camera operator 1 joined AGAIR in July 2021. They were not employed as a pilot by the organisation, but they held a commercial pilot licence (aeroplane), issued in February 2020. At the time of the accident, they had about 434 hours total aeronautical experience, including 72 hours on multi-engine piston aircraft.

Medical

Camera operator 1 held a class 1 aviation medical certificate that was issued on 14 November 2022 with no restriction. The medical certificate was valid at the time of the accident. Their aviation medical records were provided for the period 2021–2022. These examinations indicated no significant medical conditions or abnormal physical findings. Camera operator 1 was reported to be in ‘very good health’ with no known medical conditions.

Camera operator 2

Aeronautical experience

Camera operator 2 was a United States citizen who had experience in the construction and operation of the imaging system fitted to VH-HPY (see Aerial survey camera system). They joined AGAIR in October 2023, and had conducted 5 line scanning flights in VH-HPY prior to the accident flight. They did not hold a flight crew licence, but they had received about 4 hours instructional flight training in the year prior to the accident.

Medical

Camera operator 2 did not hold an aviation medical certificate, nor were they required to. They were reported to be ‘very healthy’ with no known medical conditions.

Post-mortem and toxicology

Autopsy results

The post-mortem examinations determined that the occupants of the aircraft had sustained multiple injuries during impact that proved fatal. The results of the examinations did not indicate any significant natural disease that could have contributed to the accident. However, the examinations were limited due to the nature of the impact and resulting fire. There were no indications that the occupants of the aircraft had inhaled products of combustion.

Toxicology results

Toxicology testing was conducted and no drugs were detected, however the validity of the testing was degraded due to changes that occur post-mortem. Alcohol and carbon monoxide testing could not be completed using the samples obtained.

Aircraft information

General information

The Gulfstream 695A is a high-wing, pressurised, twin-engine aircraft powered by 2 Garrett TPE331-10-511K turboprop engines. The aircraft was designed as a business and personal aircraft with seating capacity of up to 11 people.

The accident aircraft, serial number 96051, was manufactured in 1982 and in January 1983 commenced operations in South Africa. During this time the aircraft’s air conditioning system was replaced with an approved alternative system.[10] In 2014, prior to the aircraft being exported to Australia, the aircraft underwent refurbishment, which included a new avionics suite and interior, and the aircraft was repainted. Additionally, the original Dowty Rotol propellers were replaced with Hartzell propellers under a supplemental type certificate.[11]

The aircraft was first registered in Australia as VH-HPY on 11 November 2014. Its registration was held by AGAIR since 14 September 2016 and was initially used for birddog flights[12] (Figure 5).

The aircraft was configured with 2 crew seats, 4 passenger seats, and a bench seat in the rear. The last periodic inspection was completed on 1 November 2023. At this time, the aircraft had accumulated 7,566.1 hours total time in service.

Source: Cameron Marchant

Aircraft systems

Aerial survey camera system

To expand its operational capabilities, AGAIR elected to modify VH-HPY to undertake aerial surveys of natural disasters such as bushfire and flood by fitting an Overwatch Imaging TK‑7 camera system.

To modify the aircraft, AGAIR engaged an approved aircraft design organisation to prepare the engineering order,[13] and the installation was carried out by General Aviation Maintenance (GAM). Work on the modification began in June 2021 and had been partially completed when the aircraft recommenced operations in August 2021. In November 2021, VH‑HPY returned to GAM and the modification was completed and certified on the maintenance release.[14] The engineering order, associated drawings, and a flight manual supplement specific to VH-HPY, were approved by the aircraft design organisation in February 2022.

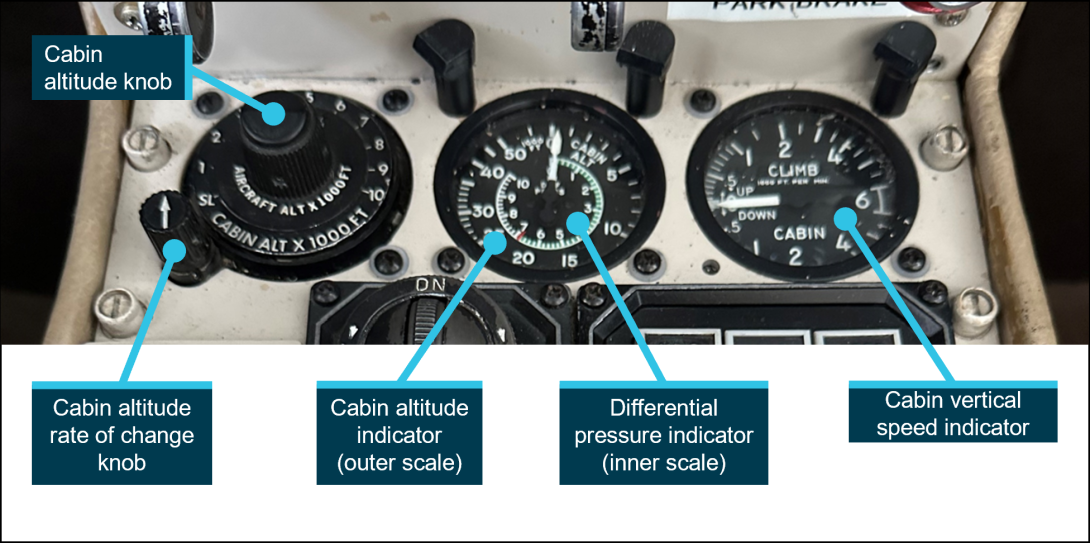

Pressurisation system

Generally, aircraft that are intended to be operated at altitudes over 10,000 ft are equipped with a pressurisation system. As the aircraft climbs, the air pressure outside the cabin decreases, and at the same time the aircraft’s pressurisation system maintains the pressure inside the cabin to a level that allows normal breathing (without the use of supplemental oxygen). The environment maintained by the pressurisation system is known as the cabin altitude. The difference between the pressure inside the cabin and the pressure outside the cabin is known as cabin differential pressure. Pressurised aircraft have a stipulated maximum differential pressure because of the loads that pressurisation places on an aircraft’s fuselage.

The Gulfstream 695A is pressurised by ducting air from both engines (known as bleed air) into the cabin and controlling its flow overboard via outflow safety valves to maintain the desired cabin pressure. The source of bleed air can be selected within the cockpit. A cabin pressure controller, also located within the cockpit, is used to manage the cabin pressure from take-off, through climb, cruise, and descent. The controller also prevents exceedance of the maximum differential pressure of 6.8 psi (see Appendix A – Gulfstream 695A systems information). The Gulfstream 695A is certified to operate up to 35,000 ft above mean sea level. At this altitude, and at the maximum differential pressure, the cabin altitude would be 9,600 ft. The pilot’s operating handbook (POH) requires the pilot to ‘limit flight altitude to maintain 10,000 ft cabin altitude’ should the cabin altitude exceed the selected value.

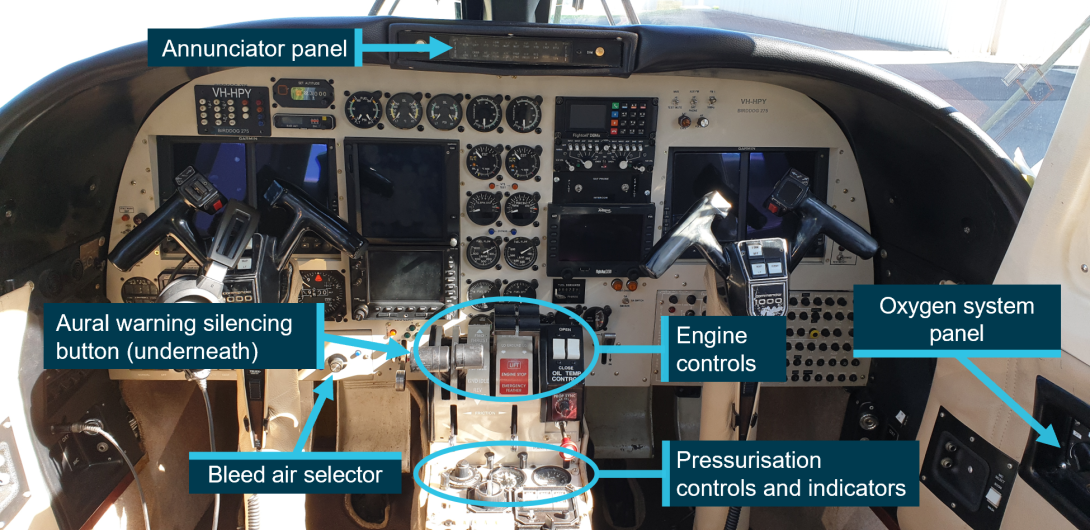

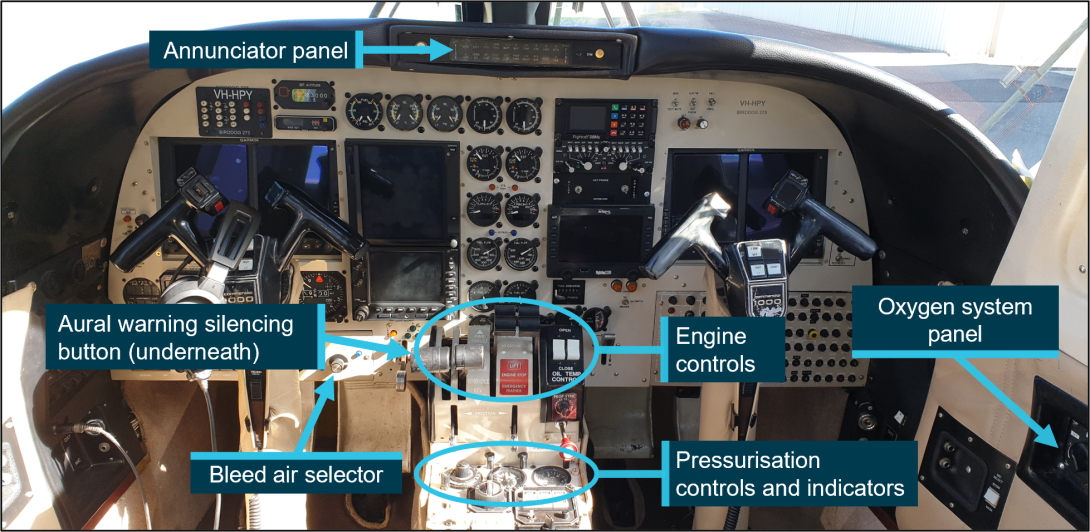

Figure 6: VH-HPY cockpit layout

Note: Image captured prior to the accident. Source: Cameron Marchant, annotated by the ATSB

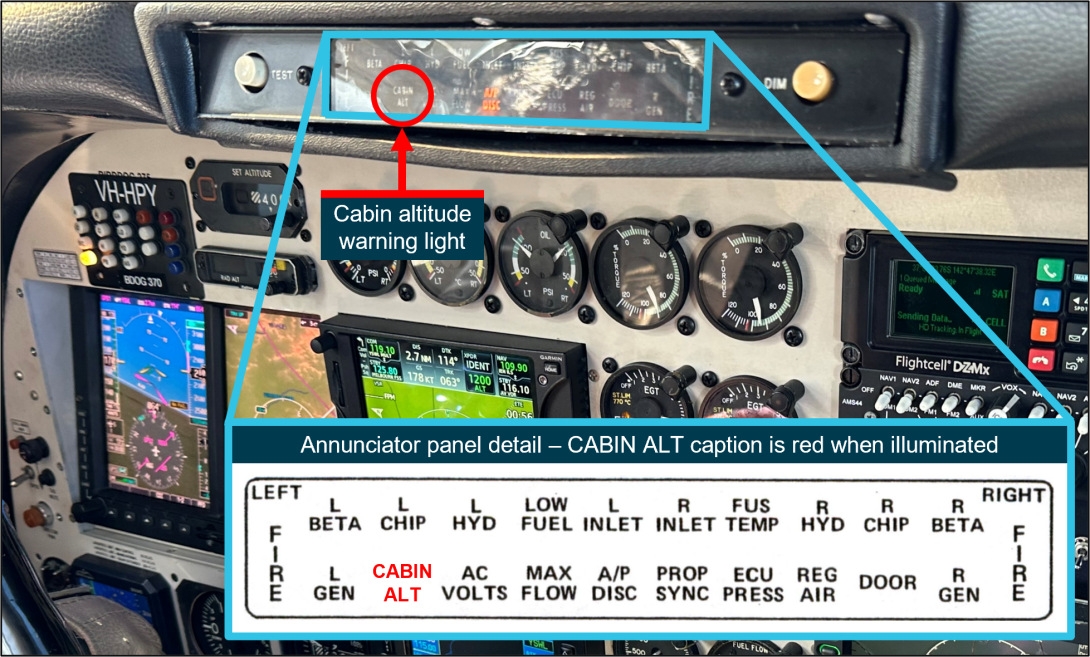

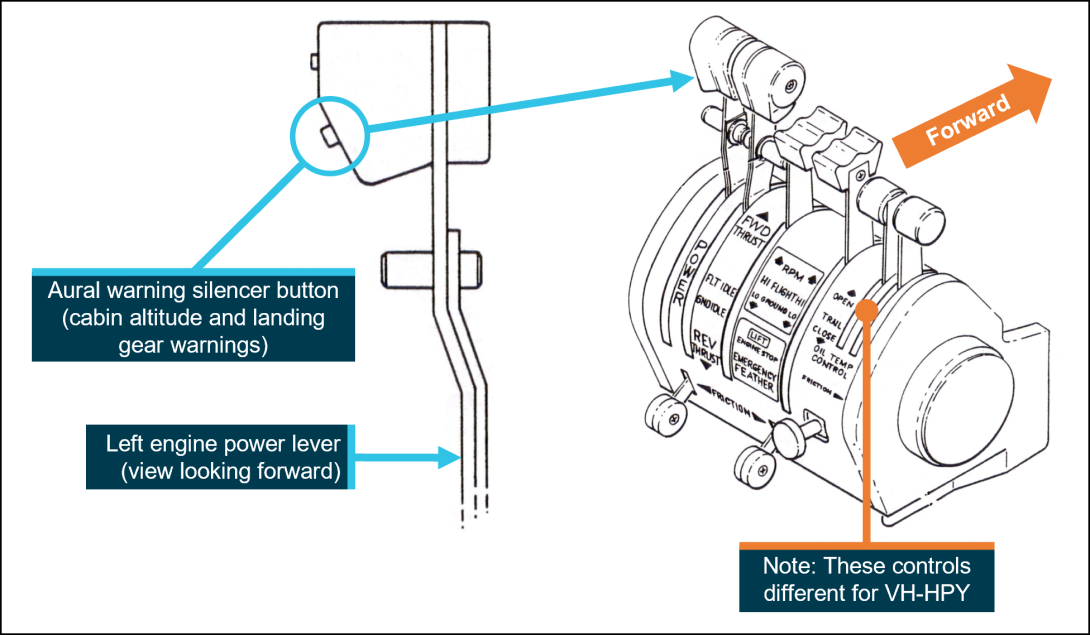

The Gulfstream 695A is fitted[15] with a cabin altitude visual and aural warning system that activates when the cabin altitude is at or above 11,000 ft (±500 ft) (Figure 6). When activated, ‘CABIN ALT’ illuminates in red on the glareshield annunciator panel and flashes for 10–20 seconds before remaining steady. This is accompanied by an aural tone that pulses 6 times per second. The aural warning can be silenced by pressing a button on the left engine power lever (see Appendix A – Gulfstream 695A systems information).

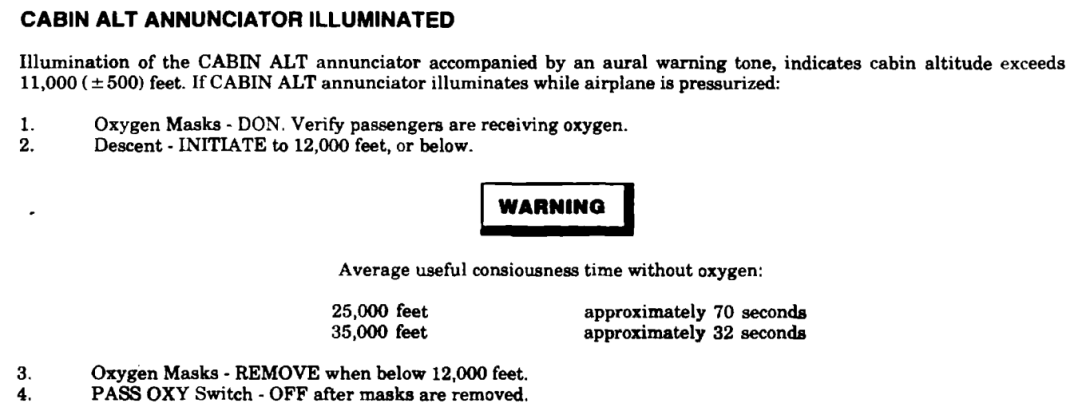

In the event of illumination of the ‘CABIN ALT’ annunciator, accompanied by the aural warning tone, the POH requires the pilot to don their oxygen mask, verify passengers were receiving oxygen, and initiate a descent to 12,000 ft or below (Figure 7).

Figure 7: Cabin altitude annunciator emergency procedure

Source: Ontic

Oxygen system

The Gulfstream 695A is equipped with an oxygen system that provides life support in the event of an emergency. The POH states that:

The airplane is equipped with a high pressure, gaseous oxygen system which provides supplemental breathing oxygen to the crew and passengers in the event of cabin depressurization during high altitude operation, or in the event cabin air becomes contaminated. The system will provide oxygen for sufficient time to permit a planned descent to an altitude where supplemental oxygen is no longer required.

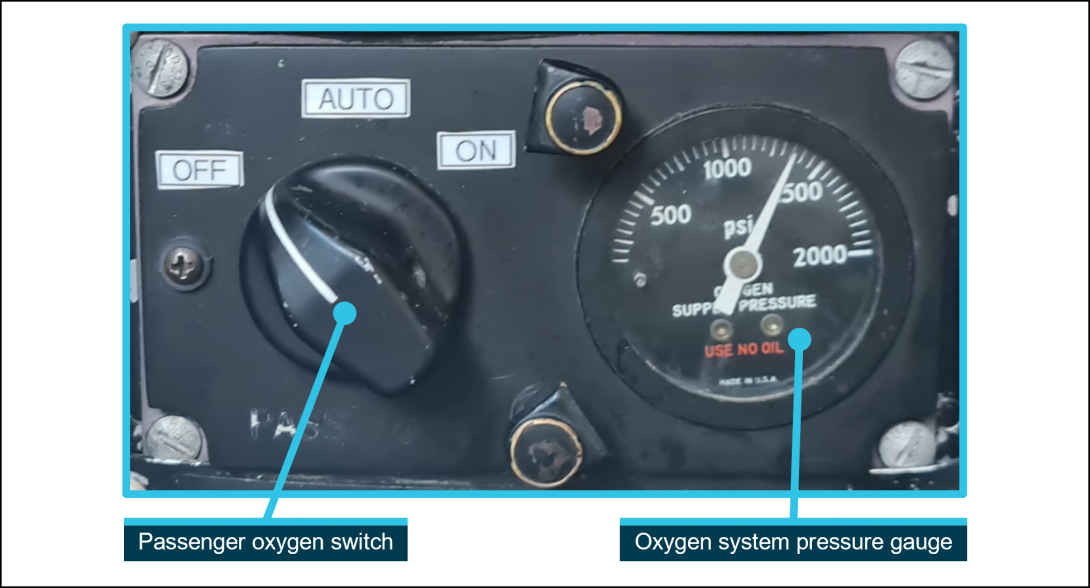

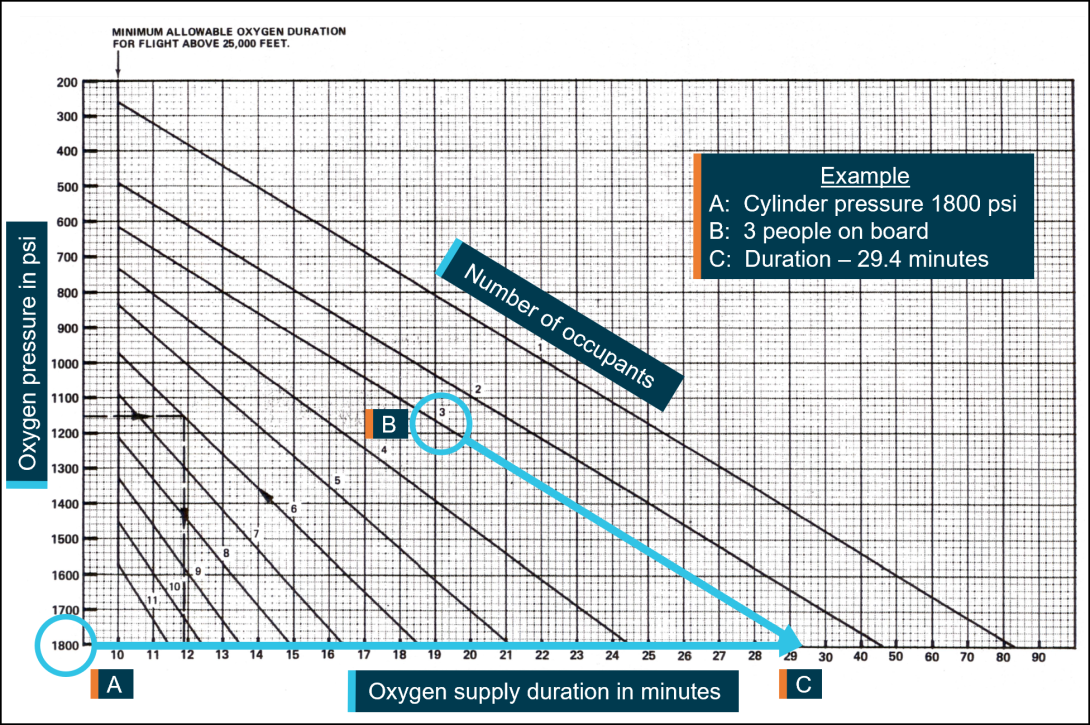

Oxygen is stored in a cylinder located in the rear fuselage and, when full, can supply oxygen to 3 people for about 29 minutes. The cylinder is full when filled to 1,800 psi. The passenger oxygen system switch is recessed into the sidewall on the right side of the cockpit, alongside a cylinder pressure gauge for the aircraft oxygen system (see Appendix A – Gulfstream 695A systems information).

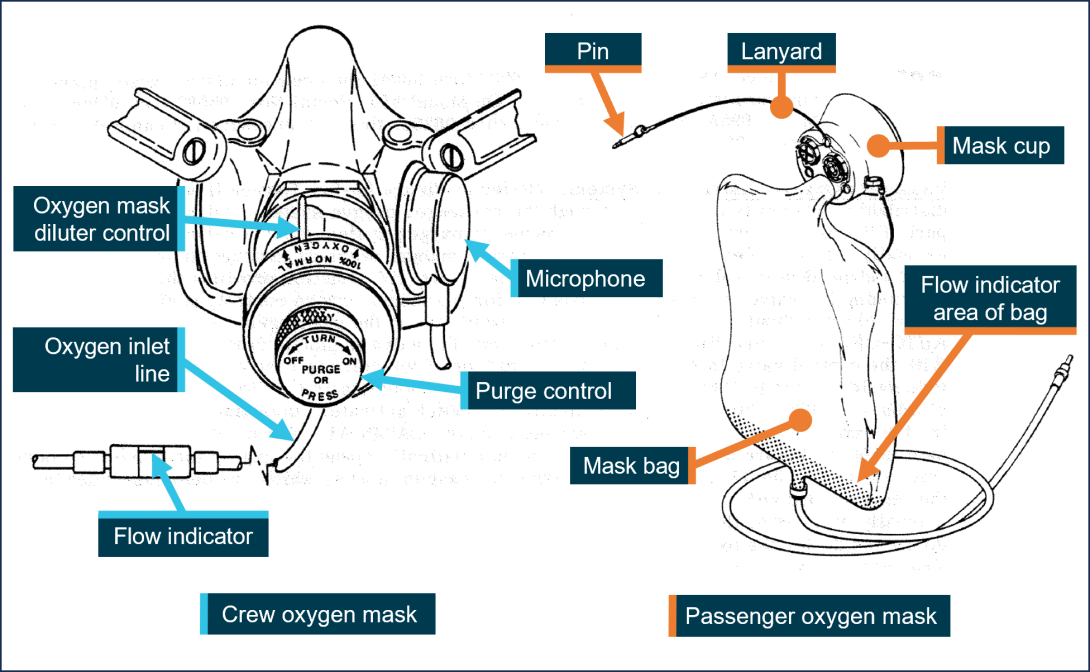

The pilot and copilot oxygen masks are designed for rapid donning and are positioned on hooks immediately behind the pilot and copilot seats for ease of access. The masks incorporate a microphone for radio communications. Passenger oxygen masks are stowed in containers at various locations in the cabin lining above the passenger seats (see Appendix A – Gulfstream 695A systems information).

Autopilot

The autopilot fitted to VH-HPY was a Collins AP-106 and it was integrated with the aircraft’s instruments. The Collins AP-106 is a 3-axis system that stabilises the aircraft about its roll, pitch, and yaw axes. The system can operate in various modes including pitch hold, heading, navigation, approach, back-course, altitude, and indicated airspeed. Both pilot and copilot control wheels have an autopilot release switch (see Appendix A – Gulfstream 695A systems information).

A subcomponent of the autopilot system, the trim servo monitor, has fault detection and diagnostic capabilities that automatically disengage the autopilot if a discrepancy or malfunction is detected. One such potential fault condition is the exceedance of threshold voltages within a servo as it works against an aerodynamic or mechanical force.

The ATSB interviewed 3 pilots who had previously flown VH-HPY for AGAIR. Two pilots described the autopilot as being unreliable at times. One recalled that the autopilot would not hold altitude well and would ‘chase’ the target by +/- 100 ft. Another recalled that the system would be fine in smooth air, but if the aircraft experienced turbulence that required multiple control inputs, the autopilot would disconnect without any prior indication after about 10 minutes. Another pilot regarded the autopilot favourably. Maintenance records for VH‑HPY show multiple instances of autopilot defects and subsequent rectifications.

Engine controls

The Gulfstream 695A engines are controlled from the cockpit using a power lever and a condition lever for each engine. The autopilot does not interface with the engine controls.

Radios

The aircraft was fitted with very high frequency (VHF) and high frequency (HF) radios, along with an additional communication unit for birddog flights and a satellite phone. Pilots wore headsets with boom microphones and were able to transmit by pressing a thumb-operated button on the outboard grip of each control wheel. Handheld microphones were also stowed on each control column.

On the day of the accident, routine communications between air traffic control and VH-HPY were via VHF. VHF radio is limited to ‘line of sight transmissions’, with communication range increasing with aircraft altitude.

Maintenance history

Recent maintenance

The ATSB reviewed the maintenance records for VH-HPY. This included records from when the aircraft was operating in South Africa (from 1983 to 2014) and the Australian records (from 2014 to 2023).

The last maintenance activity prior to the accident was carried out by General Aviation Maintenance (GAM) at Essendon Airport, Victoria, in late October 2023. The work carried out was predominately scheduled maintenance along with some minor defect rectifications. The maintenance provider also carried out checks on the left and right engine bleed air valves after being informed by the AGAIR chief operating officer (COO) that the pressurisation system was malfunctioning (see Aircraft pressurisation defects). The aircraft was released for service on Wednesday 1 November 2023, 3 days prior to the accident flight. The maintenance provider advised that after the first flight, the pilot who accepted the aircraft called and reported to them that the aircraft systems including pressurisation were working normally.

Aircraft pressurisation defects

In 2011, while the aircraft was operating in South Africa, the cabin door seal was replaced to address a pressurisation issue. In 2013 a defect was recorded where the maximum cabin differential pressure of 6.8 psi could not be reached. It was determined that cabin air was leaking from the cabin doorstep area, and this was rectified. Correspondence showed that, when preparing the aircraft to be exported to Australia, the aircraft was not capable of attaining the maximum cabin differential pressure. Significant work was carried out to rectify the issue, including major component replacements, and the cabin interior was removed for access to seal the fuselage.

When VH-HPY was purchased by AGAIR in 2016, maintenance was then provided by GAM at Essendon Airport. The aircraft was reportedly difficult to pressurise when it arrived, which was identified to be because of a leak from a sub-component of the pressurisation system known as a volume tank. Additionally, to address the pressurisation issue a few minor cabin leaks were repaired. A pilot who had flown VH-HPY when it initially entered service with AGAIR recalled that its pressurisation system did function, however if the aircraft rate of climb was high, the pressurisation system would malfunction.

Two of the pilots who had previously flown VH-HPY for AGAIR recalled intermittent pressurisation issues, where the aircraft would not pressurise higher than 2 psi differential pressure. The third pilot reported the pressurisation was okay but had noticed the high rate of climb issue. The unreliability of the pressurisation system reportedly could be managed by selecting the maximum flow of bleed air to the cabin (which can be used at any time except take-off and landing), and by turning the cabin heating up. Additionally, it was also reported that pressurisation seals in the cockpit for the rudder controls were known to leak, and during a flight in late August 2020, the seal dislodged and depressurised the aircraft. On 4 August 2023, the AGAIR HOFO said to GAM that the pressurisation system was working ‘perfectly’.

On 16 October 2023, the pilot of the accident flight emailed the AGAIR COO stating that the pressurisation of VH-HPY was ‘stuck on 2.0 differential for [a] prolonged period’ and because they needed to operate at FL280, they had ‘used a bit of oxygen’ (see Pilot of the accident flight actions). According to the Gulfstream 695A POH, operating at FL280 with a differential pressure of 2.0 psi will result in a cabin altitude of 19,800 ft. The email also requested the aircraft oxygen cylinder be refilled by a maintenance provider at Toowoomba, Queensland where the aircraft was based at the time. Records from the maintenance provider showed that the oxygen cylinder was serviced (refilled) from 1,000 psi to 1,700 psi on 18 October 2023 (see Appendix A – Gulfstream 695A systems information).

On 22 October 2023, the pilot of the accident flight emailed the AGAIR COO and chief executive officer (CEO), who also held the positions of HOFO and head of aircraft airworthiness maintenance control (HAAMC), advising them of issues relating to the pressurisation system of VH-HPY. The email stated there was ‘no change…same cycles and fixes’. The defect was described in the email as the cabin differential being stuck at 2.2 psi (see Pilot of the accident flight actions).

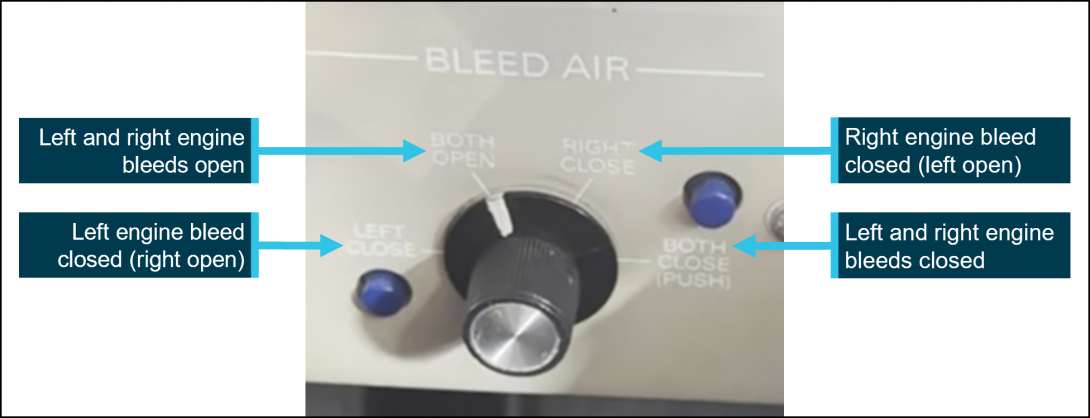

On 27 October 2023, the AGAIR COO operated the aircraft as PIC and captured a video that showed the aircraft at FL280 with a cabin altitude of 19,000 ft (see AGAIR chief operating officer actions). The COO attempted to ascertain why the pressurisation system was malfunctioning by using the bleed air selector (see Appendix A – Gulfstream 695A systems information) to shut off engine bleed air from each engine in turn. When the pilot selected ‘RIGHT CLOSE’, there was no change in cabin altitude, or when ‘BOTH OPEN’ was re-selected. When ‘LEFT CLOSE’ was selected, the cabin vertical speed indicator showed the cabin altitude climbing at 2,000 ft/min.

The video was sent to the maintenance provider and the aircraft was flown to their facility on 29 October 2023 for scheduled maintenance. The left and right engine bleed air valves were removed and functionally checked in-house before being refitted to the aircraft. The maintenance provider reported that no faults were found during the valve functional checks or when the pressurisation system was later checked on the ground. The maintenance provider stated that, prior to the completion of maintenance, the aircraft oxygen system was refilled. A maintenance release was issued on 1 November 2023 and the aircraft re-entered service.

Service letters to address cabin leaks

In September 2008, the then type certificate holder for the Gulfstream 695A, and other aircraft in the series, issued 2 service letters with guidance for addressing cabin pressurisation leaks. Service letter 382 was for aircraft in the series that were pressurised ‘to the floor’, while service letter 383 was for aircraft that were pressurised ‘to the skin’. Service letter 383 was applicable to the Gulfstream 695A and it stated:

A recurring problem in pressurized Twin Commanders is maintaining cabin pressure when flying at high altitude. This publication is presented in an effort to standardize the procedure for sealing the known and most significant leakage areas.

The service letter advised that to establish a leakage rate, the aircraft was to be pressurised on the ground using either the engines or with a pressurisation unit. Aircraft that exceeded the maximum allowable leakage rate required rectification. The service letter identified the locations where the most significant leaks occur and provided detailed instructions to address them.

Operations with unserviceable pressurisation system components

The Gulfstream 695A POH contains a minimum required equipment list (MREL) detailing components and systems that must be operable for the aircraft to be considered airworthy. It also lists components and systems that can be inoperable provided that certain operating limits were followed. For inoperative pressurisation system components, the MREL operating limitation requires the aircraft to be only operated unpressurised (see Supplemental oxygen legislative requirements).

Recording of aircraft defects

Requirements

The maintenance release document used for VH-HPY was a standard Civil Aviation Safety Authority (CASA) form 918. The document was used to identify the maintenance release period of validity, list scheduled maintenance due in that period, and to record the hours flown along with landings and pressurisation cycles.[16]

Another principal function of the maintenance release was to record defects and major damage that occurred during the maintenance release period of validity and show the actions taken to rectify them. Part 4B of the Civil Aviation Regulations 1988 did not make a distinction between minor and major defects. However, major defects were defined as:

… those that have caused, or that could cause either: a primary structural failure, a control system failure, an engine structural failure, or a fire.

Parties required to make entries (known as endorsements) on the maintenance release for defects or damage included the holder of the certificate of registration, the operator, and the flight crew. When a defect was endorsed on the maintenance release, the aircraft was not able to be flown until a formal assessment and deferral of the defect was carried out, or an entry was made to ‘clear’ the original endorsement (known as a clearing endorsement). Clearing endorsements were generally made by approved maintenance personnel, and in accordance with approved data such as the aircraft maintenance manual.

The AGAIR operations manual (OM) required the PIC to record defects and their symptoms on the aircraft’s maintenance release. The PIC was then required to liaise with the HAAMC, who would in turn liaise with the maintenance provider to determine what action was required.

Provision was given in the OM to defer defects that ‘do not impinge on the airworthiness of the aircraft’. Examples of this were given in the manual:

...the Pilot-in-command must consider whether or not the defect will render the aircraft unserviceable for a particular category or type of operation. For instance an unserviceable landing light would not render the aircraft unserviceable for day VFR operations but would render it unserviceable for night operations.

…

…some minor defects such as paint scratches or dents in the structure would not normally impinge on airworthiness whereas cracks in a wing spar certainly would.

The OM contained provision for the use of minimum equipment lists (MEL) supplied by the aircraft manufacturer. Prior to their use by AGAIR, an MEL was required to be approved by CASA, specific to a particular aircraft and operator. The MEL[17] provisions stated in the Gulfstream 695A POH were not approved for use with VH‑HPY at the time of the accident.[18]

Unapproved recording of defects

Some defects that were identified on VH‑HPY and another AGAIR aircraft, VH‑LVG, were recorded using unofficial means to the operator or maintenance provider. On 21 April 2021, the AGAIR HOFO emailed GAM requesting various tasks to be carried out on VH‑HPY, VH‑LVG, and VH‑LMC when the aircraft arrived for maintenance. The email also listed defects on each of the aircraft. None of the 4 defects listed for VH‑HPY in the email had been entered on the relevant maintenance release. Other examples included emails from the pilot of the accident flight to AGAIR managers describing a pressurisation defect with VH‑HPY (see Recording of pressurisation defects), and an internal GAM email listing defects on VH‑LVG.

The ATSB interviewed pilots who had flown VH‑HPY for AGAIR. One pilot recalled that defects would be communicated by phone to GAM. Other pilots recalled that defect lists were compiled to be rectified during the aircraft’s next scheduled maintenance.

The ATSB reviewed a total of 15 expired maintenance releases14 that had been retained with the maintenance logbooks from VH-HPY. These maintenance releases dated from November 2014 when VH‑HPY was first registered in Australia. Of these maintenance releases, 13 were from when the aircraft commenced operations with AGAIR in September 2016, and defect entries had been made on 6 of these. The defect entries had been predominately made by the maintenance provider, and the remaining 7 maintenance releases were either blank or had entries for scheduled maintenance activities.

Recording of pressurisation defects

After VH-HPY sustained an in-flight depressurisation in August 2020, an entry for the defect and a clearing endorsement was made by a licensed aircraft maintenance engineer (LAME) on the maintenance release.

Of the remaining known instances of pressurisation defects, there were no relevant entries on the aircraft’s maintenance releases (Table 1).

Table 1: Recording of known pressurisation defects affecting VH‑HPY since 2016

| Date and defect description | Approved record | Unapproved record | Rectification |

| 2016 – difficult to pressurise | No defect recorded on the maintenance release or in the airframe logbook. | Unknown | Volume tank found leaking, minor cabin leaks repaired |

| Circa 2016 – system not functioning correctly | No defect recorded on the maintenance release or in the airframe logbook. | Unknown | Maintenance action (if any) unknown |

| Multiple instances over an unspecified time of the cabin not pressurising past 2 psi differential | No defects recorded on the maintenance release or in the airframe logbook. | Unknown | Maintenance action (if any) unknown |

| 17 July 2018 – temperature modulating valve stuck, no auto temperature control |

No defect recorded on the maintenance release. Entries for defects in the airframe logbook and on GAM internal worksheets. |

Unknown | Temperature modulating valve and cabin temperature sensor replaced |

| 25 June 2019 – left and right engine bleed air shut-off valve connectors corroded |

No defect recorded on the maintenance release. Entries for defects in the engine logbooks and on GAM internal worksheets. |

Unknown | Connectors replaced |

| 19 June 2020 – cabin de‑pressurisation circuit breaker unserviceable |

No defect recorded on the maintenance release. Entries for defects in the engine logbooks and on GAM internal worksheets. |

Unknown | Circuit breaker replaced |

| 26 August 2020 – cockpit rudder control seal dislodged resulting in cabin de‑pressurisation | Entry for defect and clearing endorsement made on maintenance release by a LAME. | Unknown | Rudder control boot replaced |

| 17 November 2021 – troubleshooting a pressurisation defect | No defect recorded on the maintenance release or in the airframe logbook. | GAM invoice for the work carried out | System checks, testing of temperature modulating valve, sensors, and cleaning and bench testing of mass flow valve |

| 16–22 October 2023, multiple instances of cabin not pressurising beyond the 2 psi differential | No defects recorded on the maintenance release or in the airframe logbook. | Pilot of the accident flight emailed AGAIR managers (on 2 occasions) stating the nature of the defect and that they were using oxygen | Maintenance action (if any) unknown |

| 27 October 2023 – Cabin not pressurising beyond the 2.4 psi differential | No defect recorded on the maintenance release. Removal, testing, and reinstallation of the left and right engine bleed air valves captured under a scheduled maintenance task (bleed air system leak check). | Prior to the aircraft’s arrival at the maintenance facility, another pilot sent a video in-flight showing the performance of the pressurisation system along with a text message to the maintenance provider | Left and right engine bleed air valves removed, functionally checked, and refitted |

Meteorological information

Meteorological records[19] from the Bureau of Meteorology (BoM) at the time of the accident were reviewed by the ATSB. This predicted westerly winds at 40 kt, temperature −30°C, with no significant nearby weather events at FL280.

Meteorological conditions were also recorded by the BoM automatic weather station at Cloncurry Airport (55 km north-west of the collision location). At 1430 the surface wind was 6 kt from 190° true, visibility greater than 10 km, no detected cloud, temperature 40°C, dew point 2°C, and no rainfall since 0900.

Recorded data

The aircraft was not fitted with a flight data recorder or a cockpit voice recorder, nor was it required to be. During the accident flight, data was being transmitted by the automatic dependent surveillance broadcast (ADS-B) and Mode S transponder[20] equipment fitted to the aircraft. Flight data was also being broadcast from a TracPlus[21] unit fitted to the aircraft, which could be used by the fire services and AGAIR to track the location of the aircraft during flight. A navigational application (OzRunways) was installed on a tablet computer on board the aircraft and that device also broadcast flight data. The OzRunways data was recorded at 5 second intervals. The parameters captured from all systems were: time, aircraft position, GPS and pressure (barometric) altitude, altitude rate of change, groundspeed, and heading.

Navigation system

A Garmin GTN-750 navigation system was recovered from the accident site and transported to the ATSB Canberra technical facility. Examination of the unit identified that it was not recording flight data.

ADS-B data

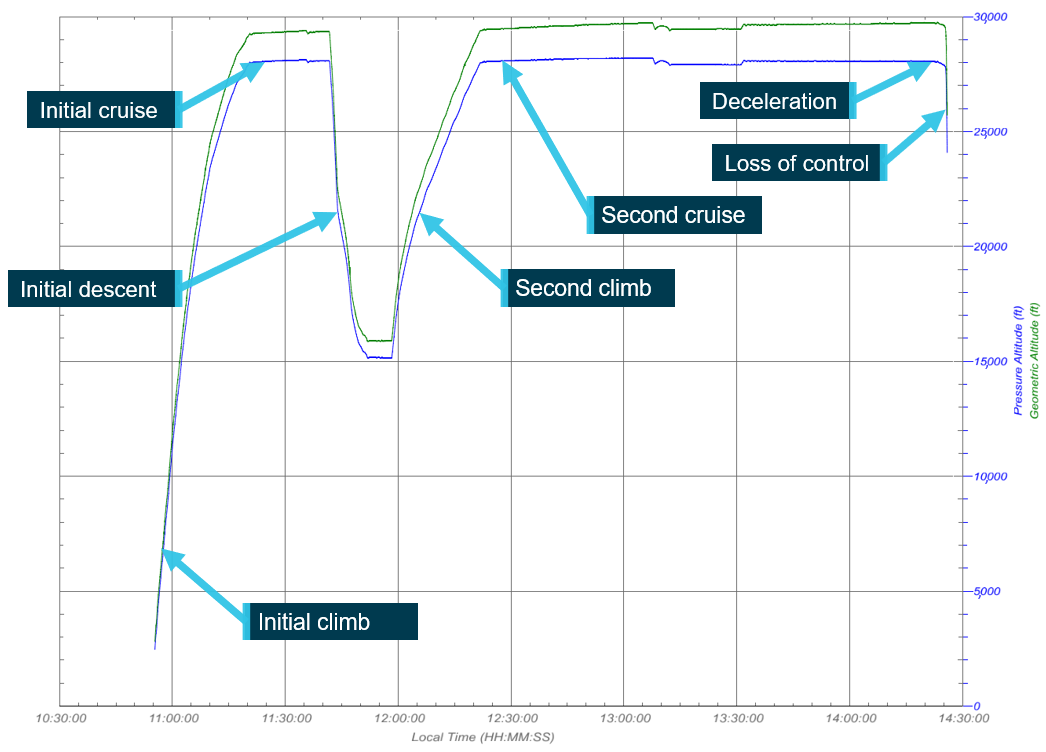

The ADS-B data provided the highest reporting frequency (~0.5 seconds), and altitude was reported to the nearest 25 ft. This data was captured from shortly after departure until the aircraft descended to about FL240 during its final descent (Figure 8).

Figure 8: Altitude profile of the accident flight throughout its duration with key moments (phases) displayed

The blue trace represents pressure altitude and the green trace represents GPS altitude. Source: ATSB

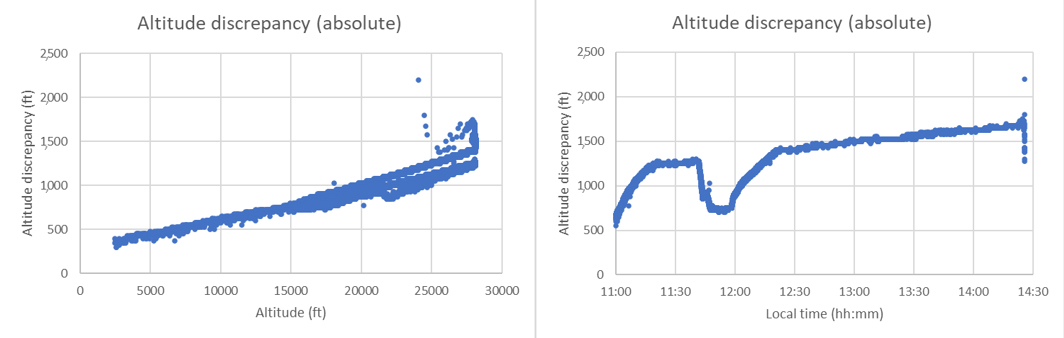

Pressure and global positioning system altitude discrepancy

The ADS-B data that was broadcast from the aircraft during the accident flight contained a discrepancy between the pressure altitude and the GPS altitude (Figure 8).[22] At the start of the second cruise phase, the broadcast pressure altitude was 28,000 ft while the GPS altitude was 29,400 ft. At the end of the second cruise phase (approximately 2 hours later), the broadcast pressure altitude was 28,050 ft while the GPS altitude was 29,750 ft. The difference in pressure and GPS altitudes over the entire flight varied with altitude and flight time and is shown on a scatter plot below (Figure 9).

Figure 9: Scatter plot of pressure and GPS altitude discrepancy with altitude (left) and over time (right)

Source: ATSB

When the above data was corrected for local barometric pressure and GPS ellipsoid modelling, the difference in altitudes at the end of the second cruise phase of flight was about 1,400 ft. The GPS altitudes from ADS-B, OzRunways and TrackPlus, which had independent GPS sources and data processing, were broadly aligned over the entire flight, and it is therefore likely that the pressure altitude was reading low and the aircraft was likely flying at FL294 (i.e. the actual position of the aircraft was likely higher than indicated). The reason for the discrepancy could not be determined, although a static source leak inside the cabin could not be discounted.

Initial descent to FL150

At 1141:12, while at FL280, the aircraft commenced a descent to FL150. The aircraft’s flight profile during this period was erratic with a fluctuating rate of descent that peaked to about 4,200 ft/min. The aircraft’s heading remained steady during the descent. The aircraft then maintained FL150 for a period of about 6 minutes before climbing back to FL280. No reason for the descent was provided to air traffic control and it was not part of the submitted flight plan. The AGAIR COO stated there was no operational reason for the descent to occur.

Flight performance analysis

General

The ADS-B, OzRunways and TrackPlus position and groundspeed data, combined with aircraft performance data, forecast conditions, and actual environmental conditions, were used to formulate likely aircraft performance during the flight. The engine power (maximum continuous power (MCP)), knots true airspeed (KTAS), knots calibrated airspeed (KCAS),[23] and vertical speed was calculated at points in time during the initial cruise, initial descent and the secondary cruise (Table 2).

Table 2: VH-HPY performance assessment

| Phase | Maximum Continuous Power setting (MCP %) | True airspeed (KTAS) | Calibrated airspeed (KCAS) | Vertical speed (ft/min) |

|

Initial cruise

|

48 | 246 | - | N/A |

| Initial descent to FL150 (period from 27,500 ft–24,500 ft) | 25 | 190 to 340 | 185 to 230 | -3,000 to -4,200 |

| Secondary cruise | 46 | 257 | - |

N/A

|

Source: ATSB

Trajectory analysis was used to estimate the likely pitch angle, angle of attack, roll angle, speed, and rate of descent for the deceleration and loss of control phases of the flight.

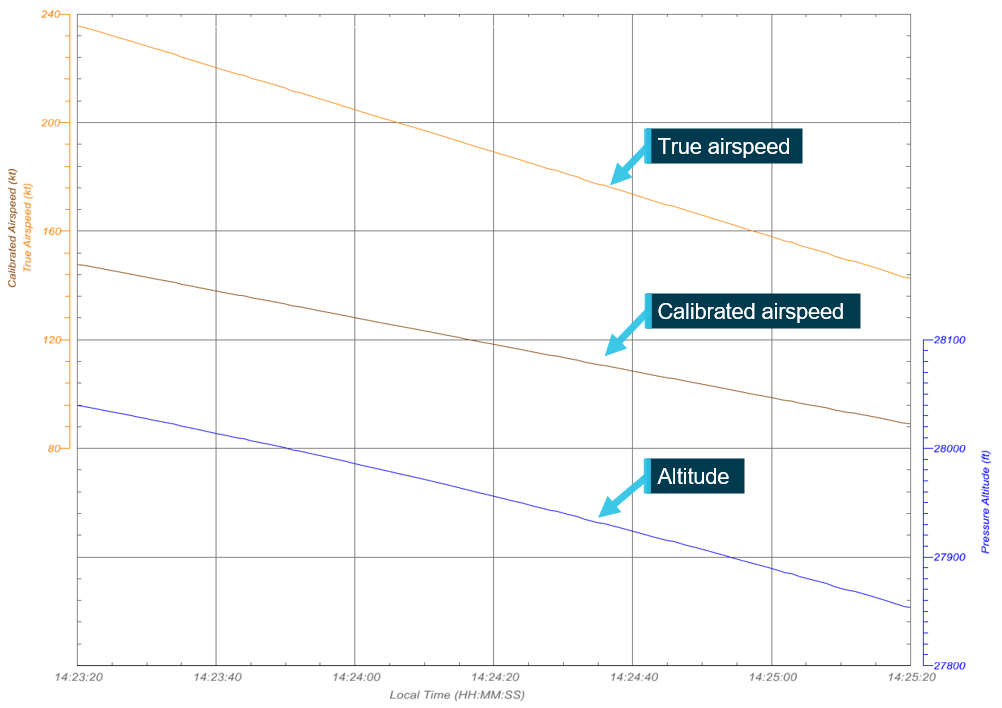

Deceleration phase

Commencing at 1423:20, the deceleration phase of the flight was assessed from 10 seconds after the transition from cruise until the start of the left descending turn (Figure 10). Over this 2‑minute period, the altitude reduced from 28,040 ft to 27,840 ft, with an initial vertical descent rate of 78 ft/min, increasing to 120 ft/min. However, over this same loss of altitude, a more substantial loss of airspeed occurred with a linear airspeed reduction from 236 KTAS (148 KCAS) to 138 KTAS (86 KCAS). This descent performance was estimated to require a power setting of about 25% MCP.

Source: ATSB

The aircraft stall speed at maximum weight was 78.6 KCAS. The corrected stall speed at the calculated operating weight of the aircraft was about 74 KCAS, 12 kt lower than the calibrated airspeed at the end of the assessed period. It was calculated that the aircraft had approximately 25% MCP applied at the end of the descent, which would slightly decrease the stall speed, giving further margin from the stall.

The minimum control speed in the air (VMCA)[24] for the aircraft was documented to be 95 KCAS. However, this speed assumes one engine inoperative with the other at MCP. Assuming in this instance one engine failed inoperative, and the other engine remained at half power (that is, total aircraft power at 25%), the minimum control speed was calculated to have been approximately 67 KCAS. This was below the power off stall speed for the aircraft weight and below the recorded minimum speed. Thus, a minimum control speed departure was excluded as a potential reason for the flight profile of the aircraft.

Loss of control

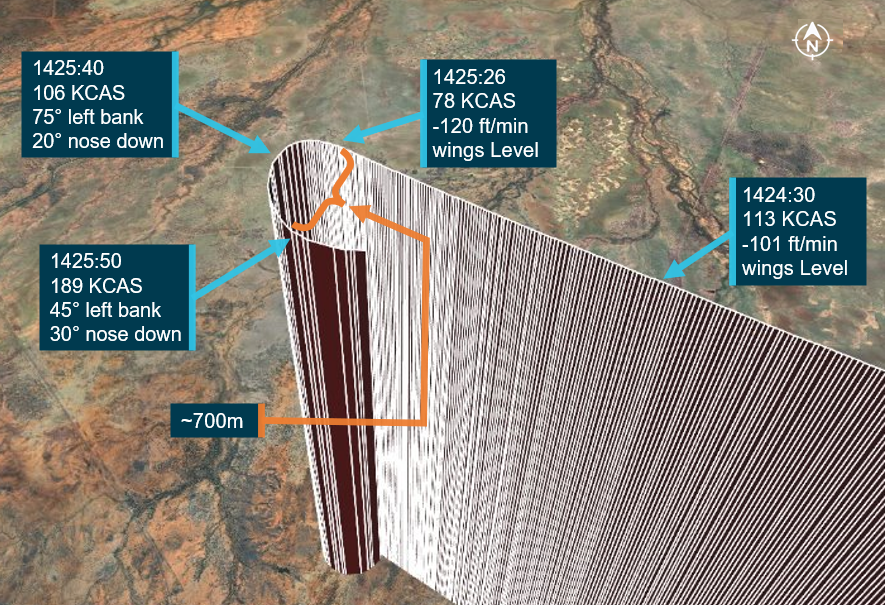

The reliability of the ADS-B data diminished as the aircraft entered the descending left turn. However, trends in the data were able to be identified. At 1425:26 and an airspeed of about 78 KCAS, the aircraft entered a left roll. The roll rate was initially about 10 degrees per second (°/s), slowing to 0°/s 14 seconds later whereby the aircraft had rolled to approximately 75° left angle of bank. The angle of attack (AoA)[25] was estimated to stay reasonably constant over this period at around 8°, indicating a fixed elevator position. However, it was calculated from the data that the aircraft pitched to about 20° nose down due to the fixed AoA and excessive roll angle allowing the nose to drop.

At 1425:40, the aircraft’s heading had turned through 85° and it had accelerated to about 106 KCAS. From this point, over the following 10 seconds, the angle of bank was estimated to reduce to around 45° and the nose-down pitch change slowed until it stabilised about 30° nose down all while the calculated AoA remained constant at around 8°. During this period, the aircraft’s heading turned through a further 100° and the speed increased to about 189 KCAS. The diameter of the turn was approximately 700 m (Figure 11).

Figure 11: Deceleration and loss of control

Source: ATSB

Because of the extreme attitude of the aircraft from this time on, the ADS‑B data and TrackPlus data became unreliable, likely due to the angle of the onboard antenna and reflected signals. The last reliable ADS‑B position information occurred at 1425:50 and at 25,500 ft standard barometric altitude and 189 KCAS. Only horizontal ADS-B position information remained valid for another 5 seconds, by which point the aircraft had turned through a ~270° track angle and crossed back through its original track.

From this point, to about 10,500 ft, all data sources became unreliable and sporadic and no conclusions about flight path or attitude could be made. However, the data indicated an average vertical speed of about −19,500 ft/min, or 192 kt vertical speed, during the period from about 25,000 ft to 10,500 ft.

At about 10,500 ft, the OzRunways altitude data stabilised and provided an average vertical descent rate of 13,500 ft/min. The final data point was at 1427:15 at an altitude of 1,800 ft.

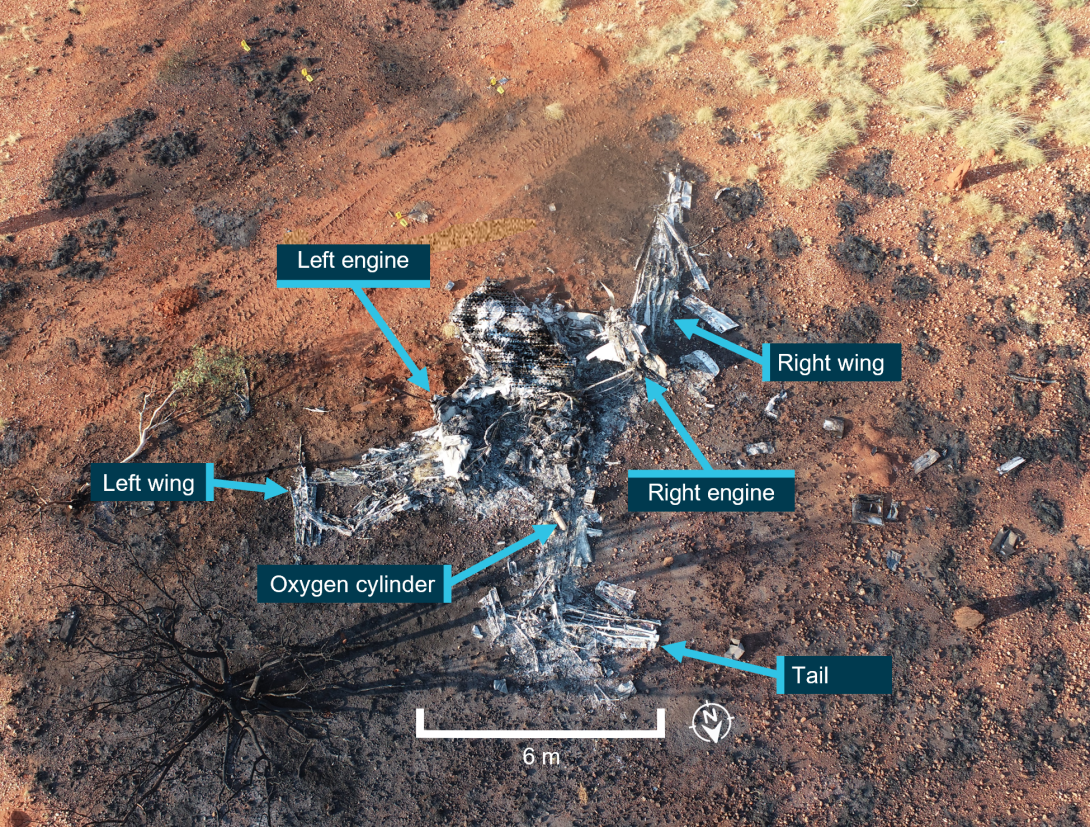

Wreckage and impact information

Accident site

The aircraft was destroyed by the impact with terrain and a subsequent fuel-fed post-impact fire (Figure 12). The ATSB conducted an onsite examination of the aircraft wreckage. The ground impact marks and wreckage position indicated that the aircraft impacted terrain upright with a shallow, nose-down attitude with little forward momentum. Immediately surrounding the wreckage, numerous landscape features (a tree and termite mounds) remained upright and had not been disturbed by the aircraft impact or its liberated debris (Figure 13). The compression and displacement of the aft fuselage relative to the engines, the displacement of the inboard wing section and the aircraft nose, showed that the aircraft was rotating clockwise on impact with the terrain, which was highly indicative of a spin.

Figure 12: Overview of the accident site

Source: Queensland Police, annotated by the ATSB

Figure 13: Heavily disrupted and burnt remnants of the wreckage at the accident site

The surrounding landscape features (termite mounds and a tree) remained upright and were not disturbed from the impact. Source: ATSB

All major aircraft components were accounted for at the accident site. The disruption to the airframe from the impact and the subsequent fire damage limited the extent to which the aircraft could be examined. The oxygen cylinder fitted to the aircraft was located in the wreckage and its associated components had been significantly fire damaged, precluding any assessment of the oxygen system’s serviceability prior to the accident. Additionally, the components comprising the pressurisation system were unable to be assessed due to the extent of damage sustained.

Engines

Both engines had been significantly damaged by the post-impact fire, limiting the extent to which they could be examined. However, the low-pressure compressor of each engine was observed to have rotational damage, indicating that the engines were operating at impact.

Propeller assemblies

Both propellers were examined and photographed by the ATSB at the accident site. Assistance was sought from Hartzell Propeller personnel to interpret the photographic evidence. They advised that there were multiple indications to identify that the engines were operating and estimated them to be at a low to moderate power setting. These indications included blade bending (in multiple planes), twisting, fractures (including multiple blade tip fractures), chordwise scoring and rotational gouges. Additionally, blades from both propellers had separated from their hubs at the shanks, and internal components were fractured.

Crew locations

The pilot was found toward the front of the cabin, camera operator 1 was behind and to the left of the pilot, and camera operator 2 was behind and to the right of the pilot. However, the impact with terrain caused significant compressional damage to the cabin area of the fuselage and the location of the crew as found within the wreckage may not be indicative of their seated location during the flight.

Fire

Witnesses from a nearby mine site who observed the aircraft during its descent did not report any indications of fire until the aircraft collided with the ground, after which a fireball and rising smoke plume were visible. A fuel-fed fire persisted after the impact, which consumed most of the aircraft wreckage. The fire was extinguished by responders from the mine site.

Survivability

The impact with terrain was not survivable.

Hypoxia

General

Hypoxia is a state where there is a deficient supply of oxygen in the blood, tissues and cells sufficient to cause an impairment of body functions. The human central nervous system demands about 20% of all inhaled oxygen to supply the brain. Any reduction in oxygen supply to the body will impact brain function, with higher reasoning portions affected first (US Federal Aviation Administration 2015). Severe exposure to hypoxia can result in the rapid deterioration of most bodily functions and, eventually, death (Gradwell 2016).

Hypoxia can result from a variety of factors including respiratory and cardiovascular deficiencies, blood disorders, pharmaceuticals and toxic substances, and a reduction in the oxygen tension in the arterial and capillary blood. The latter factor is known as altitude hypoxia, hypobaric hypoxia, or hypoxic hypoxia, and it is the most common form of oxygen deficiency in aviation (Gradwell 2016).

Altitude hypoxia

Within aviation, the typical cause of altitude hypoxia is the low oxygen tension of inhaled gas (air) associated with exposure to altitude. On ascent, as barometric pressure reduces, breathing ambient air will result in a reduction of the partial pressure and the molecular content of oxygen within the lungs. The result is an inadequate oxygen supply to the arterial blood and decreased oxygen available to the tissues (Gradwell 2016).

Clinical features of altitude hypoxia

The clinical features of altitude hypoxia are described in Table 3. In general, the greater the altitude, the more overt and serious the features of hypoxia will be. Except for a possible headache, nausea or dizziness, a pilot is unlikely to experience other uncomfortable symptoms (US Federal Aviation Administration 2015). A loss of self-criticism usually results in a person remaining unaware of their deterioration in performance and, consequently, the presence of hypoxia. It is this insidious nature that makes the condition a significant hazard in aviation (Gradwell 2016).

As noted in the table, although there is minimal impact below 10,000 ft, research has shown impaired task performance (with individuals unaware of their impairment) at cabin altitudes below 15,000 ft. With reference to the effect of altitude hypoxia on the performance of pilots, studies have shown an increase in procedural errors (Nesthus and others 1997), reduced flight profile accuracy (Steinman and others 2017), and reduced awareness of the environment (Steinman and others 2021).

Table 3: Clinical features of altitude hypoxia

| Altitude | Clinical features |

| Below 10,000 ft |

|

| 10,000 ft–15,000 ft |

|

| 15,000 ft–20,000 ft |

|

| Above 20,000 ft |

|

Source: Gradwell (2016)

Time of useful consciousness

The time of useful consciousness (TUC) is the interval between a person being exposed to a reduction in oxygen tension of the inhaled air to the time when they experience a specified degree of performance impairment (Gradwell 2016). It can also be considered the time after which an individual is no longer capable of taking appropriate corrective action to resolve the situation (for example, the use of oxygen and/or a descent to a lower altitude). The TUC does not denote the time to the onset of unconsciousness (US Federal Aviation Administration 2015).

The TUC at various altitudes is presented in Table 4. However, TUC is subject to considerable variation based on an individual’s general physical fitness, age, degree of training and previous experiences of hypoxia (Gradwell 2016). It is also affected by the rate of ascent, with a faster ascent resulting in a shorter TUC. For example, during a rapid depressurisation to altitudes between 25,000 ft and 43,000 ft, the TUC is reduced by about 50% (US Federal Aviation Administration 2015).

Table 4: Time of useful consciousness at various altitudes

| Altitude | Time of useful consciousness |

| 18,000 ft | 20–30 minutes |

| 22,000 ft | 10 minutes |

| 25,000 ft | 3–5 minutes |

| 28,000 ft | 2.5–3 minutes |

| 30,000 ft | 1–2 minutes |

| 35,000 ft | 30 seconds–1 minute |

Source: US Federal Aviation Administration (2015)

Principal aviation causes

Within the aviation context, the principal causes of altitude hypoxia are:

- climbing to high altitudes without the use of supplemental oxygen

- failure of the supplemental oxygen system, or oxygen set to an inadequate concentration and/or pressure

- depressurisation of the cabin at a high altitude (Gradwell 2016).

Post-mortem indicators of altitude hypoxia

Altitude hypoxia rarely leaves any indications that would be detectable at a post-mortem examination.

Supplemental oxygen legislative requirements

The Civil Aviation Safety Regulation (CASR) part 91 (general operating and flight rules) manual of standards 2020 required flight crew[26] to use supplemental oxygen:

- for any period exceeding 30 minutes when the cabin pressure altitude was continuously at least FL125 but less than FL140

- for any period when the cabin pressure altitude was at least FL140.

For passengers, an oxygen supply was required to be available for the entire period for any time when the cabin pressure altitude was at least FL150. Additionally, an aircraft was required to carry sufficient oxygen to meet the above requirements, and the oxygen was required to be made available through an oxygen dispensing unit in accordance with the supply requirements for that level.

Without affecting the above requirements, the same legislation also required a pressurised aircraft that was flown at an altitude of FL250 or more to have:

- at least 10 minutes oxygen supply for flight crew, even if the entire period of relevant flight was less than 10 minutes

- at least 10 minutes oxygen supply for passengers after descending below FL250 even if the entire period of relevant flight was less than 10 minutes.

The oxygen system fitted to VH-HPY complied with the legislative requirements to have a 10‑minute supply when operating the aircraft at FL250 or higher when pressurised. However, as described in Aircraft systems, the oxygen system for Gulfstream 695A aircraft was for emergency purposes (depressurisation, smoke and fumes etc) and not for the purpose of conducting normal operations (also see Appendix A – Gulfstream 695A systems information).

Operational information

Tasking

The flight had been contracted by Queensland Fire and Emergency Services (QFES) and the crew had been tasked to conduct line scanning of 10 areas of interest in Northern Queensland. The line scanning activity was to take place over 2 days, 4–5 November 2023, with the crew overnighting in Townsville, Queensland on 4 November.

Flight plan

The submitted flight plan stated the aircraft would depart Toowoomba Airport and climb to FL280. It would then fly at FL280 overhead Winton, Cloncurry, and Mount Gordon respectively, and conduct aerial work operation (line scanning) near Mount Gordon for a period of 40 minutes. The aircraft was then planned to land at Mount Isa, before travelling on to Townsville later that day (Figure 14).

Source: Google Earth, annotated by the ATSB

Fuel

The aircraft had been refuelled on 3 occasions in the 3 days prior to the accident and had flown about 5 hours. However, the quantity of fuel on board the aircraft when the accident flight departed could not be determined from the records available.

AGAIR line scanning

History of line scanning operations

AGAIR commenced line scanning operations around early 2022, following the fitment of the TK-7 Overwatch camera to VH-HPY. VH-HPY was the only aircraft within the AGAIR fleet equipped to undertake the activity. The service was initially provided on an ‘ad-hoc’ basis and in 2023 AGAIR secured a ‘call when needed’ contract with QFES. The AGAIR COO operated as pilot in command of all AGAIR line scanning flights until the pilot of the accident flight commenced operations in September 2023.

Line scanning procedures

The AGAIR OM contained a generic section on aerial photography, but it did not contain specific procedures for the conduct of line scanning operations.

The pilot of the accident flight had developed draft line scanning procedures for inclusion in the AGAIR OM. These procedures contained a section on tasking, which included information on the altitude line scanning operations were to be conducted. It stated:

The altitude missions are flown will depend on mission specifics. As a general guide for missions where a high coverage area is priority, the preference is to conduct scans as high as possible. This will ensure maximum coverage from the system while minimising the requirements for a high number of passes.

The tasking process will require refining with the clients’ requirements for considerations of weather and terrain. The imagery is affected by cloud and therefore this will dictate what height is feasible for the best product.

Generally, F200 to F280 is the most effective for large area coverage imaging. The lowest feasible altitude is 5000 ft AGL though this will be dependent on the size of the area. Large areas at this level will require a high number of passes and produce a very large volume of data.

The pilot of the accident flight had emailed the draft procedures to the AGAIR COO on 10 October 2023, but they were not incorporated into the AGAIR OM at the time of the accident.

Line scanning practices

The normal flight profile, as explained by senior AGAIR management personnel, was for line scanning operations to be conducted at FL200–FL280 as the resolution of the thermal images was not impacted by increased altitude. Consequently, the higher the aircraft flew the greater the swath[27] of the images and the more ground area could be captured in one pass, resulting in increased efficiency of data acquisition.

However, thermal imagery could be affected by cloud and, depending on the cloud coverage, may require the aircraft to descend below cloud level to conduct imaging. In those scenarios, the lower limit for the operation of the camera was about 5,000 ft.

The ATSB was advised by the AGAIR COO that transit flights to and from the fire area could be flown at any level, but transiting at FL280 would result in improved fuel efficiency in comparison to lower levels. The aircraft was also used for low level ‘birddog’ activities, where it was flown less frequently at higher altitudes.

A review of VH-HPY flights into or out of Toowoomba Airport over the period 4 September 2023–4 November 2023 indicated that 70% of flights involved a cruise at FL280. Since commencing operations with AGAIR, the pilot of the accident flight had flown 24 flights in VH-HPY as PIC, 19 of which were flown at FL280.

Operations at high cabin pressure altitudes

AGAIR chief operating officer actions

During interview, the AGAIR COO stated that they occasionally experienced the intermittent defect with VH-HPY’s pressurisation system while conducting line scanning operations. They recalled 2 occasions where they had continued the climb while the pressurisation system was defective and used oxygen.

The earlier event occurred about 12 months prior to the accident, where the COO recalled continuing the climb while the pressurisation system was defective. They recalled using the aircraft oxygen system, attaining the cruise level, and rectifying the defect by increasing the cabin heat.

The most recent example occurred on 27 October 2023, 8 days prior to the accident, during a line scanning flight from Toowoomba with the COO, as pilot in command, and camera operator 2 on board. The COO used their phone to video the cockpit indications of the defect. The video captured the aircraft in cruise at FL280, with a cabin differential of 2.2 psi and a cabin altitude of about 19,000 ft (Figure 15). There was no audible cabin alarm on the video’s audio.

Figure 15: Inflight cockpit indications captured on video footage 27 October 2023

Source: ATSB

The COO stated that, on that occasion, the pressurisation system defect had manifested during climb, but they elected to continue to their cruise altitude of FL280 as they hoped the system would rectify itself after a short time. They stated that they maintained FL280, while using the aircraft’s emergency oxygen system as a supplemental oxygen supply, for a period of about 20 minutes before the pressurisation system ‘probably’ started working again. They also stated that they silenced the cabin altitude alerting system using the inhibit button located near the power levers. The defect was not entered in the aircraft’s maintenance release, but the occurrence was communicated directly to the maintenance provider via text message with the accompanying video (see also Recent maintenance).

The text message sent from the COO to the maintenance provider included the statement:

this was at F280 with a cabin of F200 and diff 2.2, O2 will need a top off please sir [emoji], got the job done

The COO provided line scanning training to the pilot of the accident flight in late September 2023. The COO recalled that they experienced the pressurisation defect during one of these training flights, and in that instance, they stopped at FL160 until the system functioned correctly. They recalled the advice they gave the pilot of the accident flight on the management of the pressurisation system defect was to ‘do what’s sensible and safe’.

Pilot of the accident flight actions

Documents sourced during the investigation indicated that the pilot of the accident flight had operated VH‑HPY at a cabin altitude that exceeded FL140 on several occasions. The documentation included:

- An email sent by the pilot of the accident flight on 16 October 2023 to the AGAIR COO stated:

HPY pressurisation stuck on 2.0 differential again for prolonged period. We needed F280 to complete the trip and thus used a bit of Oxygen. Pretty normal for HPY as we discussed and the pressurisation has generally been good. Oxy is still good, but we may need to do this profile again on and off. We have checked with [provider] and he has Oxygen if and when we need it. Is there anything specific re filling Oxygen on HPY that I need to be aware of? Aiming to run it down to below 500 psi and then taxi to [provider] and take it back up to around 1300-1500psi.

On the same day, the AGAIR COO replied to the pilot of the accident flight’s email, stating that they would send the pilot the relevant process from the maintenance manual so that it could be given to the maintenance provider in Toowoomba. The aircraft’s oxygen cylinder was refilled on 18 October 2023 (see Recent maintenance)