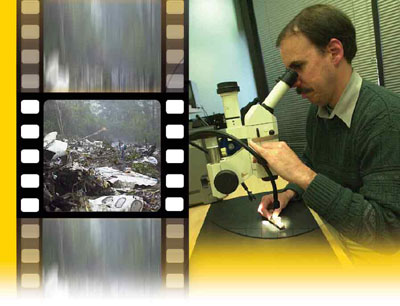

There has been an aircraft accident. Debris from the wreckage is scattered throughout a 200-metre radius. Tragically, the aircrafts crew and its passengers have been fatally injured. The sound of sirens permeates the scene as police and ambulance services attend. Soon, media representatives arrive to speculate as to its causes with cameras poised to document the wreckage.

There has been an aircraft accident. Debris from the wreckage is scattered throughout a 200-metre radius. Tragically, the aircrafts crew and its passengers have been fatally injured. The sound of sirens permeates the scene as police and ambulance services attend. Soon, media representatives arrive to speculate as to its causes with cameras poised to document the wreckage.

That this could happen so suddenly and wreak such devastation strikes at the heart of many people. An occurrence like this is always associated with a sense of urgency to understand its underlying features. But aircraft accidents are commonly attributable to a complex interaction of many factors and on-scene speculation rarely resembles the final conclusion. Often, long after commotion surrounding an accident has dissipated, a team of highly skilled experts continues to investigate the reasons for its occurrence and uncover the events that preceded it.

Scientific analysis of evidence

The interpretation of evidence resulting from an occurrence can require scientific analysis. This is the role of the Technical Analysis Unit of the ATSB, which investigates, often in painstaking detail, any structural, mechanical or operational factors related to aircraft accidents or incidents.

Failures of propulsion systems, landing gear or flight control structures, fractures in crankshafts, engine rods or turbine fan blades, abnormal aircraft speeds or flying operations are just some areas of investigation undertaken by the Unit.

Because there are myriad potential causes of aircraft safety breaches, the team of specialists working in the Unit approaches each occurrence with an assumption that it is unique.

"Investigations are rarely the same" said the Units Team Leader Dr Arjen Romeyn. "There are always new issues, new understandings to be gained. What were trying to do, ultimately, is get specific answers to questions surrounding an occurrence."

Questions can include: what was the mode and sequence of failures?; have all components performed to their specifications?; what were the mechanical settings at the time of the occurrence?; what results does analysis of the residual matter furnish?

Flight recorder analysis

To answer such questions the team uses specialist equipment and apparatus. The Unit has the capacity to download and analyse data from all civil flight data and cockpit recorders (commonly referred to as black boxes) fitted to Australian-registered aircraft. Because of its ability to establish the sequence of events prior to an accident, this undertaking can provide critical information. This is particularly so in instances where accidents have resulted in a negligible amount of recoverable aircraft wreckage or where evidence is transitory, such as occurrences involving windshear.

Even in situations where significant material evidence has been recovered an investigation can be reduced by days, or even weeks, through the retrieval of information from a flight data recorder.

Equipment for this purpose includes specialised tape decks and interfaces, and both hardware and software for signal processing and enhancing.

A radio frequency-shielded audio room, designed to prevent internal and external interference, preserves the integrity of audio analysis activities. It is also in line with the Air Navigation Act 1920, which affords protection to audio captured by cockpit voice recorders from any individuals not directly associated with its analysis, as part of an investigation.

The Unit is also equipped with advanced computer graphics software with the capacity to convert recovered data into three-dimensional animations. This capability can provide a detailed graphic reconstruction of a flight, allowing the examination of any sequence of events, from any perspective, and at any time. The benefits of this technology were demonstrated in the investigation of the much-publicised overrun of QF1 at Bangkok Airport, which occurred on 23 September 1999. Animations of the flight used for the investigation were subsequently aired on commercial television.

Materials failure analysis

Often microscopic features provide corroborating or conclusive evidence in the determination of failed components. They can also be vital to the detection of manufacturing assembly, maintenance or operational abnormalities, such as fractures in engine mechanisms or defects in airframe components.

Microscopes utilised in the Unit include: a low-power stereo microscope for general observation, which has the capacity for magnification of up to 50 times; a reflected-light microscope for the examination of the internal structures of materials, which has the capacity for magnification of up to 1000 times; and a scanning electro-microscope which magnifies from 14 to 300,000 times the actual size of an object. In addition, this microscope has an x-ray analysis facility for determining the chemistry of small material items.

The team approach

According to Dr Romeyn, while the array of equipment used in the laboratories is impressive, the Units most important assets are the highly skilled investigators who staff it.

"There is a perception that, because we work in a technical area, its the equipment that does the work and were just operators. To do our job we need particular tools, but that's all they are. Its the understanding of what the tools allow us to see that's important", said Dr Romeyn.

Core skills necessary to undertake the work required of the Unit include a high degree of understanding in the ways mechanisms operate and their environmental affects, an appreciation of design issues, an awareness of how structures function and the ability to identify failure modes.

These skills are reflected in the academic backgrounds of the Units five investigators which comprise advanced qualifications in metallurgy, aeronautical engineering and electrical design engineering. According to Dr Romeyn, however, while knowledge of these areas is vital, it is not in itself sufficient.

"Safety investigative work is a complex system and its the depth of understanding that is important. You don't gain that just by doing a degree. Its a continual learning process and experience is an essential component of the success of our work", said Dr Romeyn.

Dr Romeyn also acknowledges the importance of contributions made from other areas of speciality. In any investigation a range of skills are applied and this is just one skilled area. It is very important to talk to a wide range of people. Investigators with expertise in such areas as cabin safety and human performance, as well as individuals from the wider aviation industry, can be vital sources of information. Its the coming together of experience that provides the basis for fruitful investigation, said Dr Romeyn.

Often pro-active measures are initiated from work performed by the team. On 13 October 2000, while on a climb out of Hobart, a Boeing 737 experienced a dramatic malfunction in one of its engines which caused a reaction consistent with explosion. The aircraft landed safely and its pilot and passengers were unharmed. By analysing the factors surrounding the incident, the team identified deficiencies in a procedure used to repair cracks in turbine blades. Pursuant to these findings, the operator of the aircraft modified repair procedures to prevent recurrence.

According to Dr Romeyn, initiating such improvements to existing safety defences is a critical aspect of the work of the Unit.

"In the context of our work, pro-active investigations are those directed at events which haven't threatened safety directly but have the potential to do so. We know that little things can trigger big accidents. In a way, we operate as independent auditors of the aviation system", said Dr Romeyn.

Aircraft accidents and incidents can have significant, immediate and long-term affects on those involved. The determination of underlying factors takes time and months can lapse between an occurrence and the official release of findings related to it. However, investigations into occurrences, such as those undertaken by the team of the Technical Analysis Unit, can furnish illuminating explanations as to what went wrong and how safety can be improved.