An interim report from an ongoing Australian Transport Safety Bureau investigation has detailed the sequence of events of a loaded iron ore carrier’s grounding in a channel while departing Port Hedland, Western Australia.

The interim report, which details factual information established in the investigation’s evidence collection phase but contains no analysis or findings, notes that in the early hours of 9 April 2022, Liberian-flagged bulk carrier Hagen Oldendorff departed its berth at Port Hedland, with a harbour pilot onboard.

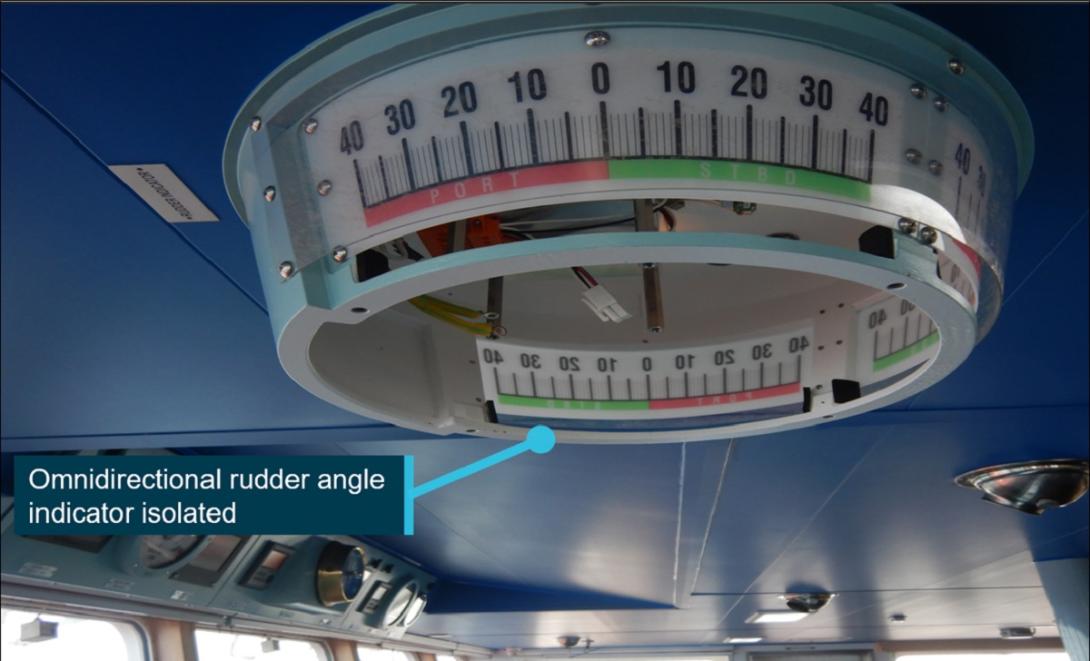

About 50 minutes after departure, the ship was travelling through the harbour channel at 6.8 knots, with one tug connected to its stern and two others closely following, when the pilot observed the lighting extinguish on the rudder angle indicators.

As the ship had begun to swing to starboard, the pilot ordered port rudder, and the tug connected to the ship’s stern to pull the stern to starboard, to counteract the swing.

Recorded data from the ship’s voyage data recorder (VDR) shows the ship subsequently began to swing to port at an increasing rate.

To counteract this port swing, the pilot directed the tug to pull the stern to port, but also ordered the ship’s rudder ‘hard to port’. The ship’s master followed this direction, but then queried it after about 30 seconds. Subsequently, the pilot asked for the rudder to be put hard to starboard instead.

The rudder angle indicator failure meant the pilot and ship’s crew were unable to ascertain the rudder’s position, or whether it was responding to commands.

While the ship’s rate of turn to port reduced after this change, it was not enough to prevent it grounding on the edge of the dredged channel.

“Upon coming into contact with the channel’s edge, the ship’s bow swung away from the side of the channel, back to starboard,” ATSB Chief Commissioner Angus Mitchell said.

“With tugs assisting, the ship was taken out to anchorage for inspection.”

A post-incident inspection found the tracking motor of the bridge’s omnidirectional rudder angle indicator had burnt out, causing a short circuit which tripped the circuit breaker, causing a power outage in all the rudder angle indicators available on the bridge.

An underwater hull inspection identified substantial damage, including holes in the ship’s port side and bottom shell plating, and the failure of the transverse bulkhead between the number 1 and 2 port double-bottom water ballast tanks, allowing flooding between them.

Temporary repairs were conducted, and on 18 May the ship departed on a direct voyage to its discharge port in China. After discharging, it proceeded to the shipyard in Zhoushan, China, for permanent repairs.

As the investigation continues, it will include a review of Port Hedland Pilots’ operating procedures, practices and training regime, as well as analysis of the conduct of the pilotage and the effectiveness of bridge resource management.

It will also include a review of Pilbara Ports Authority’s policies and procedures, and a review of towage practices and procedures in Port Hedland.

Hagen Oldendorff’s steering gear arrangement, controls and indicators will also be assessed, and the ship’s procedures and emergency readiness will also be reviewed.

“Should a critical safety issue be identified during the course of the investigation, the ATSB will immediately notify relevant parties so appropriate and timely safety action can be taken,” Mr Mitchell said.

The interim report notes Pilbara Ports Authority has, since the incident, issued a marine notice requiring that a suitably qualified and competent person stands by in the steering gear room during a ship’s transit of the Port Hedland channel.

“A final report, which will detail analysis and findings, will be released at the conclusion of the investigation,” Mr Mitchell said.

Read the interim report: Grounding of Hagen Oldendorff, Port Hedland, Western Australia, on 9 April 2022