|

Key points:

|

Corrosion pitting from prolonged low-altitude operations in a marine environment probably contributed to a Dash 8 surveillance aircraft’s engine failure on take-off, an Australian Transport Safety Bureau (ATSB) investigation has found.

The Surveillance Australia operated Bombardier DHC-8-315 aircraft with four crew on board was about to start its take-off roll from Darwin Airport on 11 November 2019. With the brakes on, power was applied to both engines. On reaching take-off power, and prior to brakes release, the crew heard a loud bang. The crew aborted the take-off and shut down the engine, while air traffic control advised the crew of smoke from the right engine.

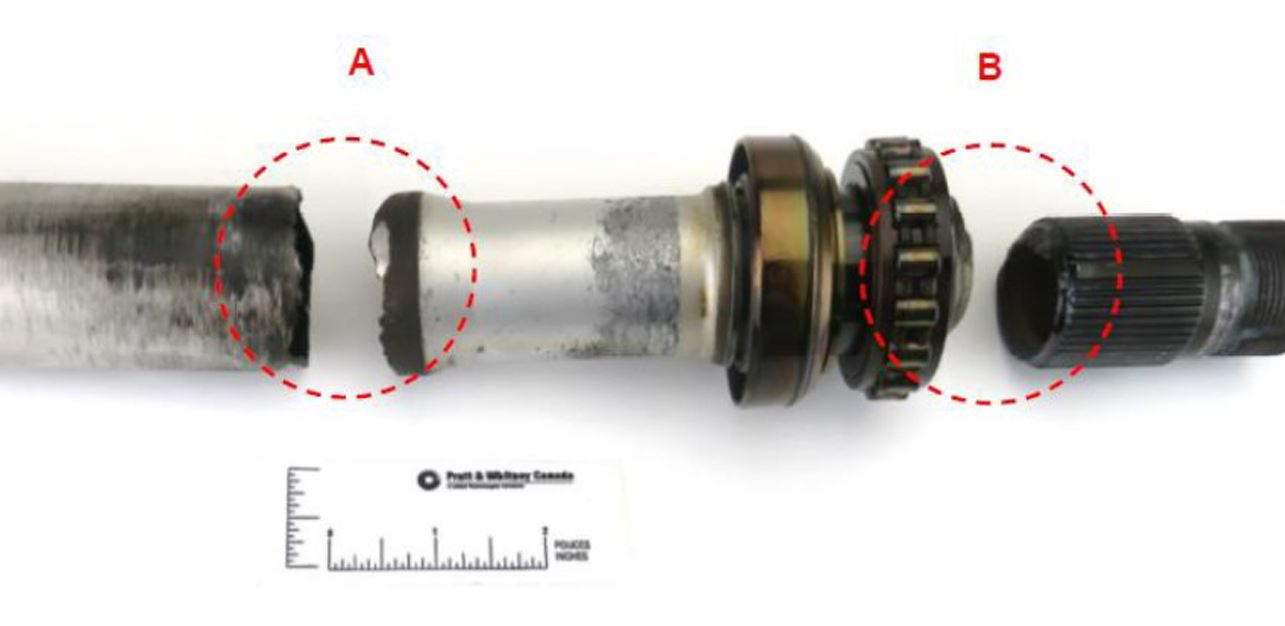

After the aircraft had returned to the maintenance hangar, a runway inspection identified metal fragments behind the aircraft’s take-off position. An external inspection of the right engine revealed significant damage to the power turbine assembly.

“The ATSB’s investigation found that the power turbine shaft of the aircraft's right engine fractured due to fatigue cracking, resulting in secondary damage and engine failure,” said ATSB Director Transport Safety Stuart Macleod.

“The fatigue cracking initiated at corrosion pitting, which was probably associated with prolonged low‑altitude operation in a marine environment.”

The power turbine shaft originally installed in the engine was replaced during its first overhaul in 2011 due to excessive corrosion pitting. However, the maintenance organisation did not escalate the finding of corrosion to the engine manufacturer, Pratt & Whitney Canada (P&WC), possibly due to the informal reporting process at the time (formal guidance and criteria for reporting such findings was established in 2018).

The ATSB also identified that the power turbine shaft in P&WC PW100 series engines operating in certain marine environments is susceptible to corrosion pitting, which can grow undetected between scheduled inspections, increasing the risk of shaft fracture and engine failure.

“The corrosion-related fracture of the power turbine shaft of the aircraft’s engine in this occurrence highlights that corrosion pitting that exceeds repair limits on safety‑critical components should be a warning sign to manufacturers, maintainers, and operators that the existing maintenance strategy may not be effective,” said Mr Macleod.

“Additionally, manufacturers should provide guidance and criteria to maintenance organisations for assessing and reporting corrosion on safety‑critical components. This enables identification of whether the maintenance strategy is effective or if changes are required to reduce the risk of in‑service failures.”

P&WC has advised the ATSB it has commenced a review of historical overhaul experience of the power turbine shaft in an effort to identify which engines and operators are potentially exposed to an increased risk of shaft corrosion.

Additionally, P&WC has also proposed a range of safety actions to address the identified safety issue concerning the corrosion-related fracture of power turbine shafts in PW100 series engines that should complement its formalised reporting process. This includes considering a borescope inspection of the power turbine shaft between overhauls during hot section inspections with defined corrosion inspection criteria and investigating a method to remove contaminants from inside the shaft during service. Additional mitigating action for engines within the PW100 engine fleet that have completed hot section inspections, but are potentially exposed to the risk of power turbine shaft corrosion, is also being assessed.

“While the proposed actions should address the safety issue, no timeline for their implementation was provided. As such, the ATSB has issued a safety recommendation to P&WC to support its proposed actions to avoid a similar shaft fracture from occurring,” said Mr Macleod.

Read the report: Engine failure during take-off involving Bombardier Dash 8, VH-ZZE, at Darwin Airport, Northern Territory, on 11 November 2019