|

Key points:

|

Flashing lights and boom gates were not activated at a North Geelong level crossing when an Overland passenger train passed through as protections had been inadvertently removed for planned track work.

An ATSB investigation report into the 8 January 2019 incident found that, in preparation for signalling upgrade works, the Thompson Road level crossing was to be isolated for the broad and dual-gauge tracks only. However, the level crossing protections for the adjacent standard-gauge track were also deactivated.

“Level crossing protections for the standard-gauge track, as used by the Overland passenger train service, was to continue operating as normal until a second stage of works at the site at a later date,” said acting ATSB Director Transport Safety Kerri Hughes.

“However, the signalling tester, following the provided isolation plans, mistakenly isolated the level crossing for an upcoming second stage of works at the same time as for the initial stage of works.”

As a consequence, as the Adelaide-bound Overland service 3MA8 approached the level crossing, the train crew noticed that the flashing lights had not activated and the boom gate had not lowered. In response, they commenced braking, reduced the throttle, and sounded the horn to alert approaching road traffic.

“The train passed through the crossing at a reported speed of about 50 km/h, with the level crossing protections inactive,” said Ms Hughes.

“Although there was road traffic in the vicinity, no vehicles were on the crossing at the time the train passed through.”

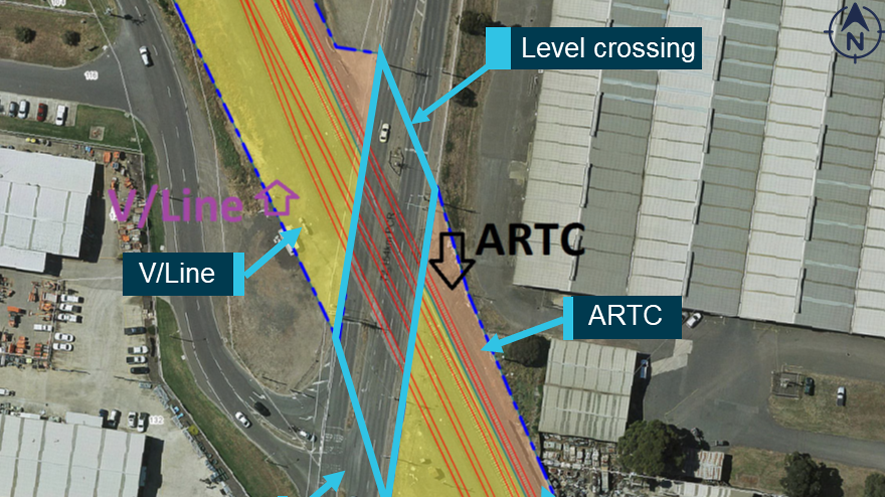

The signalling upgrade work, managed by VicTrack and contracted to UGL Engineering, involved the removal, modification and installation of new signalling equipment. Stage one of the project involved the isolation of crossing protections for the V/Line-managed broad-gauge and dual-gauge tracks, with the level crossing protections for the adjacent ARTC-managed standard-gauge track to operate as normal until the start of a second stage of works.

The ATSB found that there were no supporting instructions in the plan specifically detailing the scope of work for each stage.

“The contractor undertaking the work did not provide signalling testers with specific instructions detailing the scope of work to be conducted at each stage of a project, but rather, only provided packaged isolation plans for the entire project,” Ms Hughes said.

“The absence of these instructions increased the risk of the works being incorrectly implemented.”

This investigation highlights the importance of providing clear, concise, and detailed work instructions to reduce the risk of errors during critical safety work, Ms Hughes noted

“Work instructions are step-by-step guides on how to perform a specific task or activity, in support of a process or procedure. They are important defences within a safety system for ensuring work is performed safely and as intended.”

In response to the incident, VicTrack now includes specific work instructions for each task associated with level crossing isolation plans.

Read the report: Level crossing irregularity involving passenger train 3MA8, North Geelong, Victoria, on 8 January 2019