A reminder that a failure to follow procedure, such as functional checks, can result in unintended consequences.

A lock-out pin not removed after maintenance meant the crew of an Airbus A320 landed at Sydney with reverse thrust inadvertently deactivated. An ATSB investigation found a maintenance team had deviated from procedures, probably due to operational pressure.

Prior to the incident, the aircraft had undergone a three-day maintenance check at a facility in Brisbane. Two days in, the engineers identified that the horizontal stabiliser actuator required replacement, which added a half day of work to the schedule. To recover the lost time, the team was organised to begin work at 0400 the following day. Then the aircraft departure time was brought forward, and the engineers were instructed to complete the maintenance by the end of first shift. Many of the engineers worked through their lunch breaks to ensure they could complete the maintenance on time.

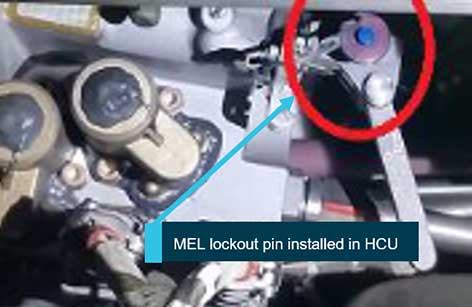

While working under the compressed schedule, engineers deviated from the written procedures, and the incorrect lockout pin was installed and then not removed later. As a result, the aircraft was returned to service with the thrust reverser system inadvertently deactivated.

There was no damage to the aircraft, or injuries as result of the incident.

The safety message from this investigation is that functional checks are the last line of defence in maintenance work. Failure to follow procedures, such as functional checks, can result in unintended consequences. Additionally, it is imperative that aircraft maintenance engineers feel empowered to stop a process when they observe procedural violations or foresee that an error is likely to occur.

Read the report: Engine thrust reverser malfunction involving Airbus A320, VH-VGZ, Sydney Airport, New South Wales, on 20 September 2018