On 8 March 2013, during climb after departure from Tyabb aerodrome, Victoria, the pilot and sole occupant of a Jabiru J430 aircraft, reported the onset of vibration through the airframe.

As a precaution, the pilot began to turn the aircraft back towards Tyabb. During the turn, the propeller separated from the aircraft, necessitating a forced landing upon tidal flats at the western edge of Westernport Bay. The pilot was not injured and was able to disembark the aircraft safely.

A potentially serious accident was avoided by the pilot’s adherence to emergency procedures and maintaining control of the aircraft after a significant mechanical failure.

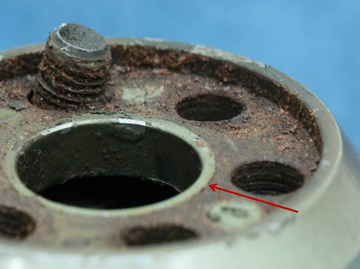

The ATSB investigation found that most of the cap screws connecting the propeller mounting flange to the engine crankshaft had failed by bending fatigue fracture – principally due to repeated relative movement between the mounted components. This movement was traced to a combination of an ineffective, multi-step torqueing method and the relaxation of tension within the crank–flange joint due to the compression of multiple layers of paint within the joint. It was also found that there were some anomalies within the maintenance documentation that related to these areas.

After attempting to analyse the origin of the worsening vibration in the aircraft, the pilot correctly followed emergency procedures both before and after the propeller loss. The over-water return decision limited the risks associated with the forced landing, and the pilot effectively maintained control of the aircraft throughout the descent and landing.

In July 2011, the manufacturer had improved the strength and reliability of the crank–flange joint by adding positive-location dowels in all new-production engines. However, that modification was not extended to earlier design assemblies, which included VH-TJP. The current (revised) issue of the Engine Overhaul Manual has an added strong recommendation for inclusion of these dowels at the next full overhaul or at bulk strip of engines manufactured prior to July 2011. Furthermore, in addition to the earlier requirement for no paint on mating faces or where screw heads bear, a broad requirement was introduced to ensure that no paint, thread-locking compound or contaminants remain in the propeller flange joint. The fastener torqueing method has been amended to a single-step process in which the required torque is to be obtained dynamically while the fastener is being turned.

Finally, the manufacturer’s Propeller Flange Attachment Service Bulletin now refers maintainers directly to the engine overhaul manual for installation procedures – removing the variability that previously existed between documents.

A potentially serious accident was avoided by the pilot’s adherence to emergency procedures and maintaining control of the aircraft after a significant mechanical failure.

Regarding the mechanical assembly, the ATSB encourages manufacturers and maintainers to consider older and legacy operating assemblies when designs are optimised or improved to enhance safety and reliability.

Read the final report: Propeller loss involving Jabiru J430, VH-TJP, north of French Island, Victoria, on 8 March 2013